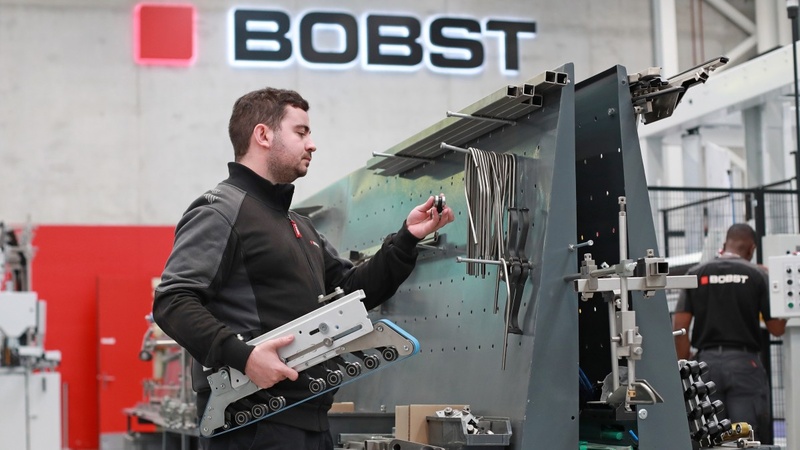

Performance, safety and productivity achieved through the right parts and consumables

In the packaging industry, where quality, efficiency, and productivity are crucial to operational success, ensuring your printing and converting equipment is producing at its peak is the difference between standing out from the competition or remaining stagnant. But ultimately, is it possible to ensure your equipment always delivers the best possible performance?

Regardless of the process, the performance and final quality of your printing and converting equipment are crucial factors in customer satisfaction. Ensuring that each delivery meets technical specifications quickly, efficiently, and consistently is an even greater challenge when faced with downtime for maintenance, part replacement, or unplanned adjustments.

Gustavo Guerreiro, Zone Services Director at BOBST, explains that "The selection of spare parts and consumables has a direct impact on equipment performance. Choosing components developed specifically for each machine with the manufacturer's care and expertise, ensures a stable operation, greater durability, and reliability over time." Genuine parts not only maintain production performance but also reduce the risk of failure, increase operational safety, and protect technology investments.

Differentiators that guarantee success

Precision-engineered and rigorously tested, BOBST Original and Certified Parts are designed to ensure you get the maximum performance from your equipment, ensuring safety in the production process and reducing maintenance downtime. According to Gustavo, "By choosing original and certified components, your operation benefits from consistent performance aligned with the equipment's potential, longer component life, and reduced operational risks."

BOBST Original and Certified Spare Parts are specifically designed to work in sync with the mechanical, electronic, and safety systems of BOBST equipment. This not only ensures optimal performance but also drastically reduces the incidence of operational problems and recurring maintenance downtime, which ultimately impact productivity and product delivery speed. Another fundamental aspect is safety. In industrial environments, any deviation from operational parameters poses a potential risk. BOBST components are designed to maintain the integrity of safety systems, protecting equipment investment and team well-being.

Even the final product quality can be impacted. Thanks to the quality of the materials and special production processes, BOBST Original and Certified Parts are designed to guarantee perfect operation at each stage of production, avoiding quality deviations and ensuring a superior final product. Conversely, non-original parts often fail to meet the same technical and dimensional standards, using inferior materials and neglecting the proper quality inspections that ensure operational reliability and safety. All of these factors increase the risk of premature part wear, repetitive failures during the process, and, in the most critical cases, major breakdowns that can lead to collateral damage and, consequently, additional costs related to repairs and production downtime.

Bobst original and Certified parts

Real economy in the long run

"In the packaging industry, it's no secret that time is money. Unwanted downtime and productivity issues affect much more than just a product's delivery time, they affect the converter's wallet," Gustavo states. Minimizing machine downtime and producing with speed and quality are also characteristics achieved by choosing BOBST Original and Certified Parts.

Although the initial investment is sometimes higher than that of other alternatives, the benefits are evident: fewer unplanned downtimes, less need for technical interventions, reduced rework, and prevention of damage to other machine components. These factors directly contribute to operational continuity and reduce overall maintenance costs.

Specialized technical support is also a key differentiator. BOBST experts offer precise guidance in identifying, replacing, and installing the appropriate parts, ensuring that each component meets the expected quality and performance criteria and that your equipment returns to producing at peak performance and reliability in record time. Furthermore, genuine parts are backed by a factory warranty, offering additional protection against manufacturing defects, something not available with alternative components.

"More than a simple replacement, choosing original parts represents a commitment to productivity, quality, and safety. It's a strategic decision that preserves the integrity of the operation and contributes to achieving sustainable results," Gustavo adds.

The next time you need a replacement, consider that the value of an original part lies in its durability, efficiency and the peace of mind of knowing that your equipment is working properly at the highest level of performance.

BOBST