BOBST boosts the digital workflow on the EXPERTFOLD 145 І 165 production line

In line with its vision to connect, digitalize, and automate the converting process, BOBST has introduced the SPHERE HMI on EXPERTFOLD 145 І 165 and SPEEDPACK, enabling Job and Recipe Management capabilities for line setup.

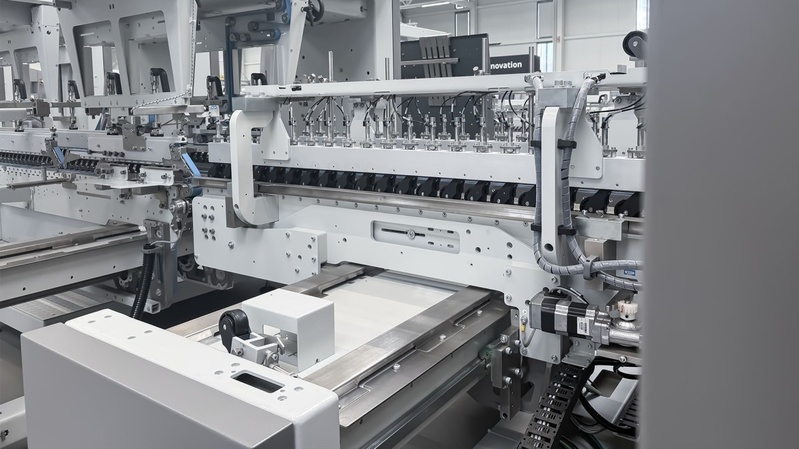

Sometimes small changes can have a big impact. This is certainly true with the latest update to the EXPERTFOLD 145 І 165 folder-gluer and the SPEEDPACK automatic packer. Both are now equipped with the SPHERE HMI, connecting the machine and peripherals directly to the BOBST Connect cloud-based digital platform. The EXPERTFOLD also features a new automated blank alignment system, which ensures fully digital, repeatable setup. This opens new possibilities for converters to boost the efficiency of their folding-gluing lines and access valuable production data with a simple click.

Introducing Job and Recipe Management Workflow

The EXPERTFOLD 145 І 165 and the SPEEDPACK are an ideal combination to create a high-efficiency corrugated and litho-laminated board converting line. Flexible and versatile, the line can be completed with GYROBOX and POLYVACUUM modules to enable production of e-commerce and multipurpose packaging in a single run. Counting, banding or strapping boxes automatically at maximum folder-gluer production speed, SPEEDPACK is designed to guarantee fluidity while maintaining box quality and increases the line productivity by up to 25%.

With the latest update, recipes for the EXPERTFOLD and the SPEEDPACK can now be prepared in the back office and sent directly to the folding-gluing line. This streamlines job preparation, enhances planning accuracy, and ensures continuous monitoring. Once a recipe reaches the machine, operators see a clear list of scheduled jobs via the HMI, removing the need to manually create recipes or consult production plans. As soon as a job is loaded, the Matic system automatically configures the key settings, and the back office is instantly notified that the job has been downloaded—marking a significant shift in operational efficiency for both operators and planners.

Operators can concentrate on the equipment, while the digital setup in the back office allows better planning and production monitoring. Improved follow-up across shifts and operator changes also facilitates continuity and precision, and any changes in the machine setup are transferred back to the BOBST Connect platform to account for any modifications.

Today, with BOBST Connect, the platform empowers converters with access to vital performance and equipment monitoring insights. It delivers comprehensive reports on productivity, variations in output quality, and machine- and plant-level production summaries. By examining data across jobs, shifts, and days, users can uncover patterns, enhance planning precision, and make well-informed, data-driven decisions.

The automated blank aligner is another important step towards the reduction of the setup time.

Speed and precision with the new automated blank aligner

The setup time reduction achieved with the Job and Recipe Management Workflow can be increased with a brand-new automation system for the alignment of the blanks at the feeder. This system adjusts the upper rollers precisely according to the box parameters for a fully automated and digital setup, which is 100% repeatable and removes the need for operators to manually adjust the blank aligning section.

Pierre Binggeli, Head of Product Line Folder-gluers at BOBST said: “The combination of digital setup and automated functionalities really has a significant impact on changeover times and cut down the operator’s workload. I think by reducing the complexity of the job and streamlining the workflow, we can have a real impact on production flexibility and efficiency.”

With additional setup time decreased for box alignment, the process becomes shorter and more predictable. Pierre Binggeli adds: “Whereas before, the quality of the setup depended on operator experience, it is now based on data. This ensures high precision, guaranteeing that every blank is positioned exactly as intended, every time.”

BOBST