NOVACUT 106 ER - Autoplaten® die-cutter

Blanking made easy

Isn’t in-line blank separation expensive and diffi cult, requiring costly equipment, all-new tooling and lots of experience? Well, not anymore, because NOVACUT 106 ER brings you a brand new – and very cost effective – solution, without the price tag or production headaches. By bringing together superb BOBST technology with our range of tooling solutions and our extensive process support network, your NOVACUT 106 ER will position you perfectly to minimize work in progress, reduce costs and so improve the productivity of your entire conversion operation.

Cutting, stripping and blanking in one go

- Produces perfectly stacked and counted batches in no time

- Significantly reduces workload and related costs

- Full sheet delivery for short non-repetitive jobs, allowing easy shift from stripping only to blanking

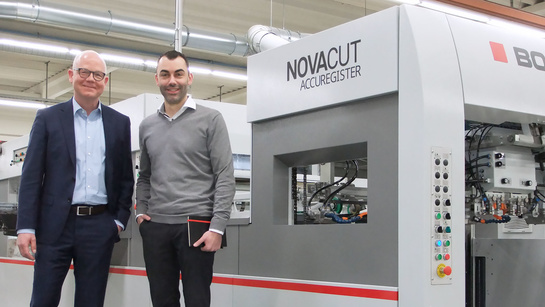

Unique technology made affordable

- Various unique technical features, ensuring easy job setting and remarkable product quality

Profitable, reliable, long-lasting

- Excellent price/performance ratio

- Robust, reliable machine made to last

- Access to BOBST tooling solutions, service and spare parts network