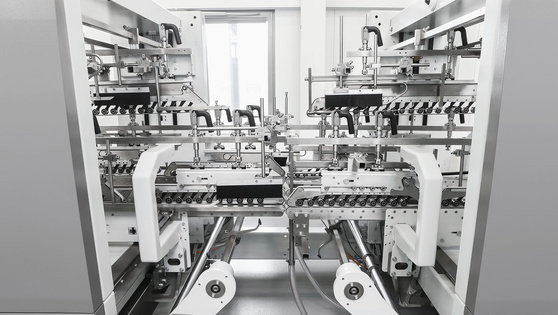

EXPERTFOLD 145 | 165 - Folder-gluer

ACCUFEED

- Integrated BOBST blank aligner with wider conveyors, ensuring perfect folding quality on heavy flutes

- Alignment left or right

- Feeds all types of material

- Pneumatic locking feature for feeding ramps which reduces set-up times by up to 5 minutes and improves significantly machine ergonomics

- An optional automated blank aligner in combination with the Job and Recipe Management Workflow allows to cut down setup time of the feeder

Prebreaker

- High speed, variable angle prebreaking with extra-long module

- Ensures reliable and precise opening of the finished product

- Lifting device allowing quick and easy set-up

- Extra wide lower belts and driven upper belts for regular blank transport, even for heavy materials

Crash-lock module

- Motorized lifting frames for fast and easy set-ups

- Quick setting, for short makeready and changeover

- Allows a huge range of box variants to be run

- Prebreaks large boxes and provides a location for additional devices

4 & 6-corner devices

- Runs a large range of box types

- High-speed and high quality folding with modulated hook trajectory

- Easy setting with electronically controlled rotary hooks

- Tilting frame adjusts to flap size

- SPHERE controlled, allowing saving and retrieval of settings

Folding

- Crease relief device for more natural, smooth and precise folding

- Crease control device ensuring a perfect fold

- 5 meter long folding section for perfect gap and reduced fishtailing

- Driven upper belts ensure more consistent transport, especially for heavy blanks

ACCUEJECT XL

- Easily set quality control device, able to eject a single faulty box

- Automatically ejects non- standard boxes up to 35 mm thickness at full running speed

- Ensures high quality production while simultaneously reducing waste and costs

Transfer

- Independent drive for total control of the box stream

- ACCUSQUARE XL for perfect alignment of every box, guaranteeing high standard quality

- Belt tensioning and adjustable height ensure a prefect box stream

- Adjustable transfer conveyors for quicker set-up

Delivery

- Independent drive for faster changeover

- Box-stream regulator for precise intervals, higher quality and faster running

- Improved glued box quality with automatic apron centering

Ergonomics

- Maximum accessibility for fast set-ups and direct process control

- Easy handling and quick makeready with MATIC setting and remote control

- Complete production overview with LED machine status indication and video monitoring

- Security light barriers for maximum safety

Job and Recipe Management Workflow

Connects the HMI SPHERE via the BOBST Connect platform directly to the back office, where job recipes can be managed away from the production floor. Then, the job recipes are sent to the production lines and equipments, ready to be downloaded.

This system allows to increase uptime and proactively prepare shifts. Taking into account changes occuring during production, it ensures production consistency and continuous improvements across different shifts and operators. It also gives a real-time follow-up of the packaging production progress.

Monitoring and management

Analyse and improve your production workflow and planning with BOBST Connect. With Performance Management and Equipment Monitoring, reports provide data which give insights into productivity and output quality as well as a comprehensive production overview of all connected machines.

Energy Monitoring allows to control the air and electricity consumption of the machine and identify eventual energy saving measures.

EXPERTFOLD 165 e-commerce

The creativity, productivity and capability of EXPERTFOLD 165 can be further increased with two groundbreaking inline devices: GYROBOX and POLYVACUUM. These modules enable the production of e-commerce and other complex, multipurpose boxes in just one single pass, allowing to produce a wider range of boxes while lowering costs. Create new business opportunites and giving you decisive advantage in the packaging market by increasing the flexibility and efficiency of your folding-gluing production line.

POLYVACUUM

- Module for in-line application of strips, self-adhesive tapes and special folding devices

- Lower vacuum transports for perfect stability of the blanks

- Bespoke upper transports allowing the installation of external application tools

GYROBOX

- Rotate blanks from 0° to 90° in any direction

- Rapidly produces complex designs in a single pass, particularly e-commerce boxes in a single production line

- Allows great diversification and adaptability, increasing efficiency and lowering costs

Productivity and diversification

- Operating speed up to 250 m/min

- No hindrance and no loss of speed when running standard boxes

- High precision, guaranteeing the superb quality of the final product to ensure client satisfaction

- Greater diversification and flexibility for increased competitiveness, creating new business opportunities