EXPERTFOLD 50 | 80 | 110 - Folder-gluer

HMI SPHERE

- Controls all functions the machine

- Up to two 15” full color, high-definition touch screens

- Simple step-by-step procedure guides the operator through the job set-up process

- All settings appear on one screen for more convenient and intuitive navigation

- Fully compatible with the digital BOBST Connect platform

- Allows the saving of up to 5,000 job settings

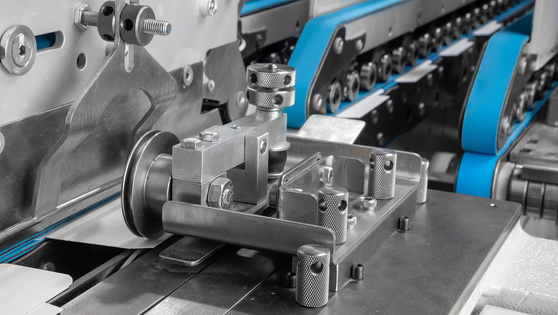

ACCUFEED

- Integrated blank aligner for perfect folding

- Variable-speed independent drive ensures faultless feeding of irregularly shaped cartons

- Feeds all types of material

- Pneumatic feeder ramps can be unlocked and locked at the flick of a switch, considerably cutting down setup time

- Reduced waste

- Less maintenance

Prebreaker

- Maximum prebreaking of all boxes at high speed, regardless of material

- Extra-wide, left-hand lower belt ensures no marking

- Upper-left conveyor displacement allows for more flexibility

4 & 6-corner device

- Fast set-up of all types of 4- and 6-cornered boxes

- Automated and precise lateral positioning of the main elements via HMI with optional MATIC system

- Speeds of up to 28,000 b/h

- Cable guides for 45° panel which suit all box sizes

- Modulated hook trajectory for high-speed, high quality production

- Transparent security doors, reducing footprint at the back of the machine and offering space for tool storage

Crash-lock module

- Processes multiple-fold packaging

- Provides a location for supplementary devices such as label inserters

- Telescopic upper conveyors are easily adjustable to box format

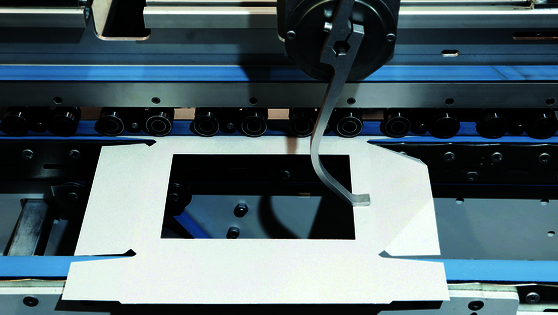

Folding

- Minimum folding device for folding down to 35 mm

- Choice of left, right or simultaneous folding

- Automatic belt tensioning ensures quicker makeready

Lower gluing unit

- Oversized stainless steel glue wheel for high speed running

- Unique scraper device with micro-metric adjustment for precise gluing

- All components easily removable for quick cleaning

- Independent motor keeps gluing station active while machine is in standby, allowing energy savings and maintaining glue quality

Transfer

- Independent drive for complete control and faster job changing

- Synchronized kicker adjusts to carton arrival time

- Adjustable transfer conveyors adapt to difficult box shapes

- ACCUEJECT ejects non-conform boxes

- Belt tensioning and adjustable height ensure a perfect box stream

Delivery

- Integrated box-stream regulator for precise stream intervals and faster running

- Automatic apron centering improves box quality and prolongs belt life

- Infeed conveyor for better control of boxes with irregular edges

- ACCUPRESS enables easy recall and reset of multi-pressure zones through SPHERE, reducing setup time and improving final product quality, especially for sensitive and crash-lock boxes

Job and Recipe Management Workflow

Connects the HMI SPHERE via the BOBST Connect platform directly to the back office, where job recipes can be managed away from the production floor. Then, the job recipes are sent to the production lines and equipments, ready to be downloaded.

This system allows to increase uptime and proactively prepare shifts. Taking into account changes occuring during production, it ensures production consistency and continuous improvements across different shifts and operators. It also gives a real-time follow-up of the packaging production progress.

Monitoring and management

Analyse and improve your production workflow and planning with BOBST Connect. With Performance Management and Equipment Monitoring, reports provide data which give insights into productivity and output quality as well as a comprehensive production overview of all connected machines.

Energy Monitoring allows to control the air and electricity consumption of the machine and identify eventual energy saving measures.

A3 Version

The new multi-purpose EXPERTFOLD A3 Version, has been developed to drastically simplify and reduce changeovers on your EXPERTFOLD 110, increasing your productivity and shortening your lead time while maintaining high-quality production. According to the box type, changeovers can be reduced by up to 80%, pushing versatility and efficiency even further.

- Additional combifolder modules for 4-& 6-corner boxes production, drastically reducing tooling changes

- Up to 80% changeover time decrease when changing from crash-lock bottom to 4-& 6-corner settings

- According to box types, changeovers can be done in 5 minutes

GYROBOX

This supplementary module for the EXPERTFOLD 110 revolutionizes the production of complex boxes. Rotating blanks in line between two folding processes, in one single pass, it makes the folding-gluing of complicated carton packaging quick and easy and delivers exceptional end-product quality. GYROBOX boosts the efficiency of your production process.

Complex boxes in one go

- Rotates blanks from 0° to 180° in any direction

- Produces complex boxes, such as double-folded boxes, rapidly and in one single pass

- Simplifies the production process and cuts down costs

Production

- Simple to set up

- Can be left in line, even when not needed

- No hindrance and no loss of speed when running standard boxes

Versatility

- Superb quality of the final product

- Maximizes creativity, productivity and efficiency

- Increases diversification, flexibility

- Opens up new markets

SPEEDWAVE 2

SPEEDWAVE 2 is a BOBST patented device that simplifies the setting of crash-lock and various other special boxes on your EXPERTFOLD 80 | 110, saving you time while simultaneously delivering exceptional folding quality and drastically increasing your productivity.

Set-up

- Greatly reduced setting times

- Highly ergonomic : one button for all settings

- Motorized set-up of the wave

- Synchronized positioning of lower lateral guides and the wave

- 80% less tooling to be set in the machine

Production

- Exceptional folding quality

- Significantly higher productivity

- Quick and precise motorized set-up

- Graduated scale for precise setting of the wave

Machine

- Reduced downtime

- Hook-free folding for a more stable folding process throughout the speed range

- Better consistency

- Less noise

- Less maintenance