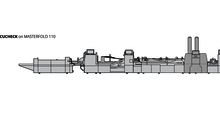

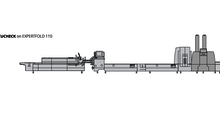

ACCUCHECK - Inline inspection system

Zero-fault packaging

The new ACCUCHECK carefully checks carton blanks for defects and guarantees complete quality consistency. Based on the 30 years' experience of BOBST's Registron technology, this highly flexible tool allows you to inspect different box areas according to different quality criteria while remaining easy and quick to operate.

Complete quality consistency

- Checks a large range of quality defects

- In-line quality check for every single box

- Automatic ejection of faulty boxes

Bespoke quality control

- Choice of operating modes for user-specific setting

- Customization of blank control areas and defect types

- Quality control reporting according to required validation targets

Cutting costs

- Making quality control process shorter and more efficient

- Reduces waste by eliminating only boxes which do not correspond to specific quality criteria