EXPERT CI - Flexo press

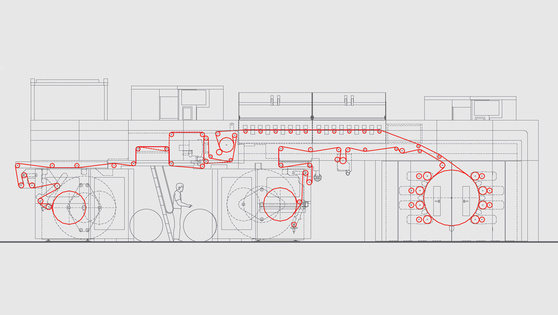

Modular concept

- The modular concept allows the machine to be customized to specific requirements. If, for example, more drying capacity is required for jobs with a high level of ink coverage at high speeds, an additional drying module can be installed on the bridge.

Rigidity meets ease of operation

- The design of the printing frames combines extreme rigidity with perfect ease of operation. On the one hand, it enables high production speeds even with the most delicate graphics, and, on the other hand, effortless sleeve, intermediate mandrel and anilox sleeve changeovers through the frame 'window'. Optional auxiliary equipment helps to facilitate the handling of large format cylinders and sleeves.

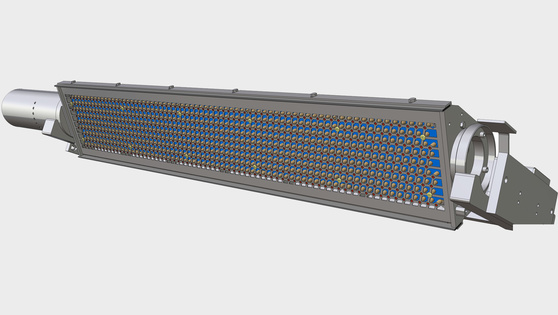

Drying system

- The floating type bridge dryer is a model of efficient performance and user-friendly maintenance access. The inter-colour dryer nozzles are easily accessible for maintenance purposes. This applies also for the nozzle between the lower print units.

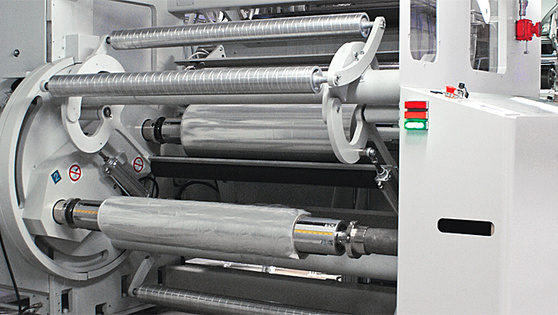

Shafted duplex winders

- The automatic shafted duplex winders enable to carry out a fully automatic bi-directional reel splice at maximum machine speed. The efficient technical solutions that optimize the use and recovery of electrical power enable an important reduction in the level of energy consumption.

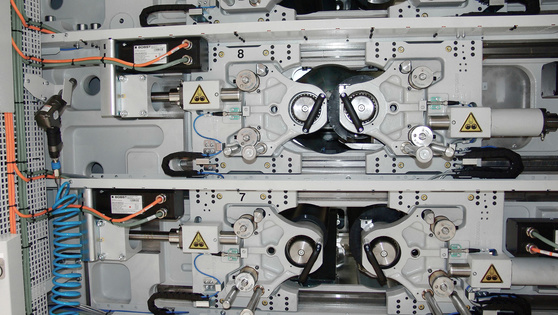

triLOCK system

- The triLOCK bearing system featuring an exclusive BOBST 3-point controlled high torque locking mechanism driven on two opposite linear guides that matches the highest print quality requirements of the Extended Color Gamut process. By eliminating manual locking, the system avoids process inconsistency and even the slightest deviation from the perfect positioning, in addition to making the work sequences easier and faster for the operator.

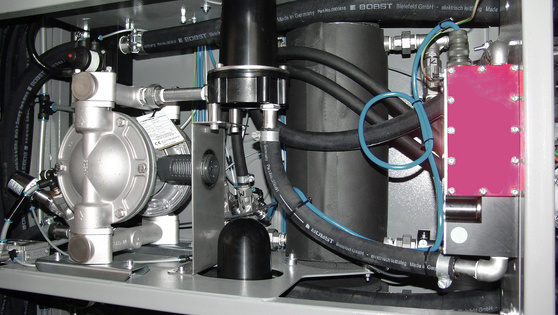

smartFLO system

- Controlled inking is of great importance in ECG printing. The features of the smartFLO inking system and chamber doctor blade, optimizing the temperature and flow of ink, deliver predictable, stable and controlled printing results with both solvent-based and water-based inks. This enables users to take full advantage of the opportunities of ECG to reduce manufacturing costs, increase consistency, and reduce errors and variables due to manual setting.

Designed to deliver superior print quality

- All the components of the EXPERT CI platform involved in printing are designed for precision in the µm range. Thanks to servo drive technology and high-precision mechanical guides, the EXPERT CI presses can handle impression adjustment, i.e. the setting of the anilox roller relative to the plate cylinder and of the plate cylinder to the substrate, with a resolution of 1 µm. Superior anti-vibration properties guarantee process consistency across all run lengths and production speeds.