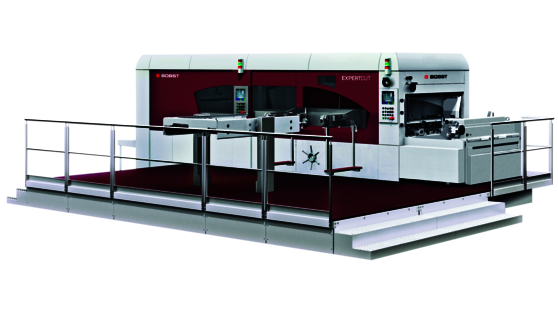

EXPERTCUT 1.6 | 1.6 PR - Autoplaten® die-cutter

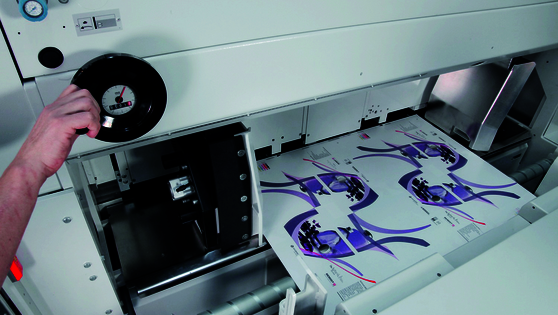

Bottom feeder

- Height adjustable rear sheet support with lateral and rear jogging for perfect sheet alignment

- Low drop, preventing possible sheet damage

- Vacuum suction plate handles all types of material from microflute to double-wall

- Optionally with integrated POWER REGISTER for perfect print-to-cut sheet registration

Platen section

- Perfect construction and minimal deformation

- Reductions in make-ready and set-up time, as well as cutting force needed

- Substantially increased machine up-time and tool life

- Paired with chase loader, productivity is further increased because the next job is prepared off-press and changeover is fast and ergonomic

Double cam gripper bar advance

- Accelerates and decelerates sheets in the smoothest way possible

- The new lower gripper position further enhances flat sheet travel, reducing stress on the sheet as it travels through the machine, allowing for higher production speeds

- Smaller nicks for improved finished product quality

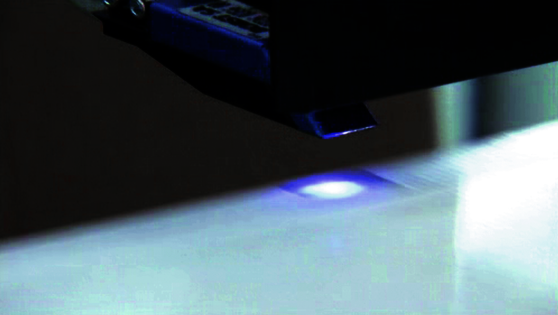

Stripping station

- Precise ejection of even the smallest waste from the most complex layouts

- Dynamic upper stripping frame with fixed central stripping board, resulting in no vertical movement of the sheet and the most perfect stripping result

- Large windows for most ease of access and faster set-ups

Delivery

- Perfectly aligned batches

- Continuous feeding device, lift on the delivery, breaking brush for high speed 6,000 s/h production and 4-8 % more productivity

- Removable dedicated lower tool for fast and easy job changeovers

- Male-female ejection tool for accurate removal of front waste, even at full speed