SP 162 CER - Autoplaten® die-cutter

Automatic lateral pile positioning

Automatic lateral shifting of the pile in the feeder of your Autoplaten® optimizes sheet travel from the top of the pile to the platen entry. By constantly lining up the pile with the register system, less correction on the sheet is needed, smoother processing is guaranteed, and superb product quality is the result.

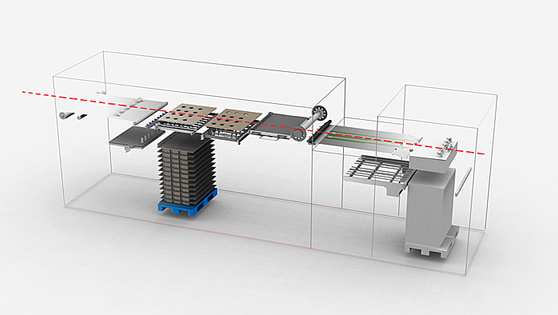

Autoplaten® concept

A BOBST Autoplaten® needs less patch-up and remains more stable during the run than any other, which means quicker setups, better product quality, and fewer stops in production. This is achieved using a principle called 'matched rigidity' which results in less deformation of the upper and lower beams when under pressure. Working hand in hand with the unique sector drive system, a tolerance free locking system for the gripper bar chains locks them into position without any vibration, giving highly accurate register, impression, and delivery.

Centerline®

Guaranteeing fast and precise tool positioning, Centerline® delivers quick machine set-ups, increased up-time, and superb finished product quality. Unique to BOBST, the patented Centerline® tool alignment system is found in every one of its flat bed die-cutters and hot foil stampers. By using a fixed master reference, which all movable elements of the machine reference to, tools can be pre-aligned, off-machine.

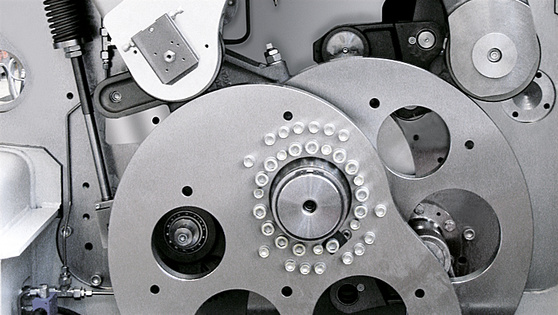

Cam driven platen

Only a cam driven platen can deliver superb quality and high net outputs. The BOBST system increases the time available for each sheet to pass so that it can be transported smoothly through the die-cutter while at the same time reducing wear on cutting tools.

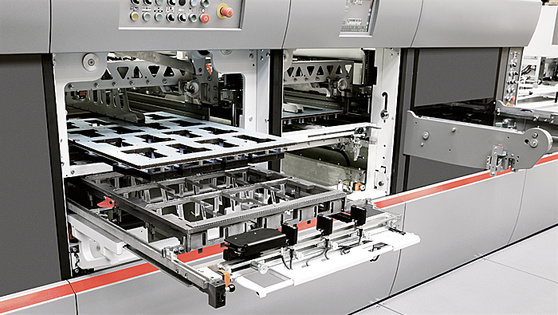

Automatic in-line waste stripping

The stripping station on a BOBST die-cutter is designed to remove even the smallest pieces of waste at full running speed. Using dedicated or universal tooling, the station is up and running in no time, delivering outstanding performance and quality, whatever the job. All BOBST Autoplaten® presses feature Quick Lock systems as standard for fast and easy makeready.

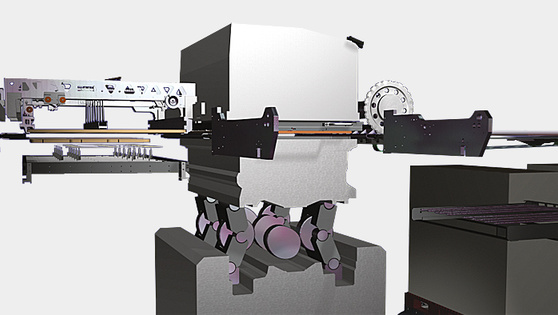

Automatic in-line blank separation

BOBST flat-bed die-cutters with automatic in-press blank separation deliver the perfect balance of force and finesse needed to blank sheets absolutely precisely, whatever the lay-out or substrate. Each BOBST blanking station is conceived to handle blanking tools from heavyweight steel units to today's lighter weight systems such as the modular Angle Lock. Functions such as continuous pile lowering, constant batch compression, and automatic tie-sheet insertion to ensure perfectly stacked piles, while the modular non-stop grid allows the highest productivity levels. Digital centering means that small variations in the tools can be quickly and easily adjusted on-press. BOBST die-cutters with blanking stations also ensure trouble-free downstream processing.