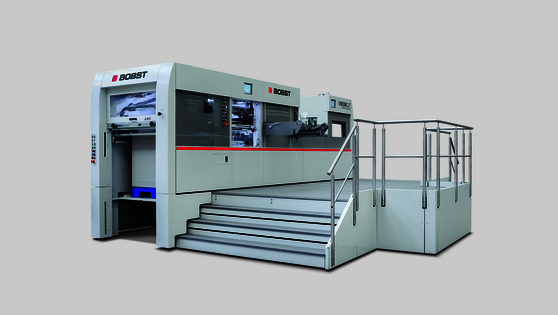

VISIONCUT 106 LE | PE | LER - Autoplaten® die-cutter

SMART FEEDER

- Manual non-stop feeder on demand for continuous production while changing piles, optimizing net output

- Continuous and stable sheet feeding with perfect material positioning and flow

- Automatic lateral pile tray correction controlled by the LATERAL REGISGER or POWER REGISTER

Feed table

- Designed to ensure smooth sheet introduction, lateral ramps aid consistent feeding

- Feed table plate reduces static and delivers smoother sheet travel

- Upper frame with pneumatic lifting device reduces work load

Optical LATERAL REGISTER

- For contact-less lateral sheet registration by identifying sheet edge, register or print mark

- Registration can be made on either side of the sheet for any type of material

- With SMART FEEDER, the system delivers optimized sheet feeding and improved finished product quality

POWER REGISTER 2

- No sheet-edge contact registration on VISIONCUT 106 PE, reducing feed related stops and assuring 100% quality

- Cameras detecting sheet edge, register marks or print itself ensuring perfect cut-to-print register

- Unique bottom print registration feature on demand for higher flexibility

Advanced HMI SPHERE

- 15” full color Human Machine Interface (HMI)

- Simple step-by-step procedure guides the operator through the job set-up process

- All settings appear on one screen for more convenient and intuitive navigation

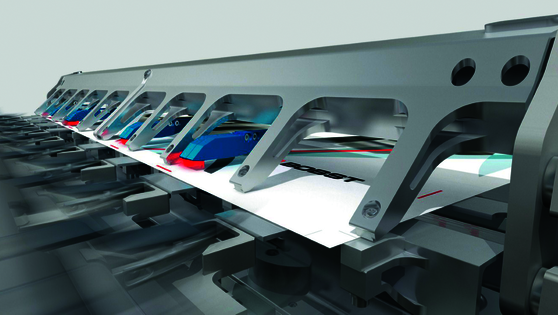

AUTOPLATEN ®

- Smoothest sheets acceleration drastically limiting number and size of nicks

- Micrometric adjustment of supporting plate

- Quick-Lock die-cutting chase for rapid and easy setting

- Motorized cutting force adjustment

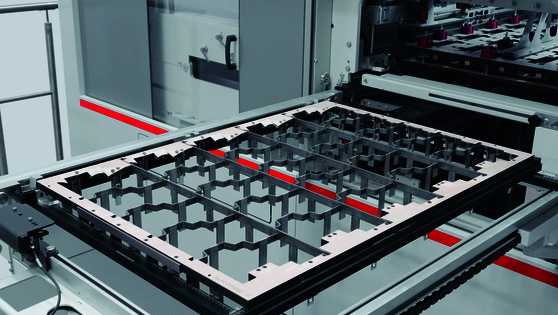

Stripping station

- Even delicate or light materials are stripped perfectly at high speed

- Quick-Lock frame for dedicated tools assuring fast job changeover

- Gripper bar opening for easy quality control during set-up

- Self-cleaning sheet braking device reducing operator intervention

Pile Delivery on LE | PE

- Optional automatic non-stop delivery for continuous production

- Perfect stacking of all types and sizes of materials

- Braking brush and blower sheet hold-down device controlled by the HMI, ensuring ideal shape of the pile

- Easy setting of front and side joggers according to CENTERLINE ®