How Rondo-Pak meets the complex requirements of the pharma industry with BOBST

The company has expanded its converting capabilities with a BOBST EXPERTFOLD 110 folder-gluer as it reaffirms its trust in the Swiss manufacturer’s technology.

Rondo-Pak in the US knows just how important it is to choose the right equipment from manufacturers that fully understand the critical nature of this sector. For many years, the company has partnered with BOBST to deliver zero-fault packaging to its customers at short notice.

Complex requirements

Headquartered in Camden, New Jersey, Rondo-Pak LLC is a leading packaging specialist in the pharmaceutical market. They produce a wide range of packaging solutions and complementary marketing materials for the world’s top pharma companies along with many other clients in the healthcare and consumer goods sectors. Part of the multi-national Körber Pharma Group, the company offers a global solution for its clients and has additional facilities in Puerto Rico, Switzerland and the Czech Republic.

Bob Reilley has spent 10 years with Rondo-Pak in the US. As President and COO, he is responsible for setting direction and managing all functions within the company. He explained, “We produce very complex structural designs to the highest quality standards for both our packaging and our marketing clients, and these require intricate and precise die-cutting, folding and gluing. Furthermore, we excel in customer services with quick lead times and on time, in-full deliveries.”

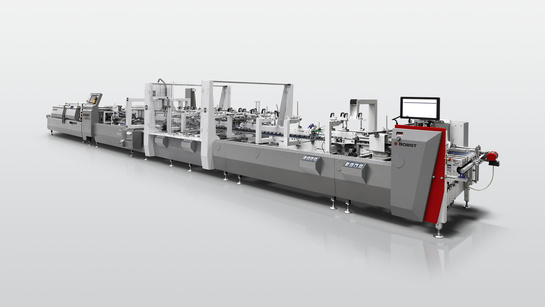

To continue to meet these very specific demands, Rondo-Pak has recently added to its existing fleet of BOBST converting equipment across its US and Caribbean sites, with the investment in an EXPERTFOLD 110 A2 folder-gluer.

“We have installed and relied on BOBST equipment for many years across all of our facilities,” said Mr. Reilley. “When making this latest investment decision, Rondo-Pak was looking to increase its capabilities and efficiencies by reducing downtime and eliminating quality defects. The equipment needed to enable quick makereadies and changeovers, to offer a high level of quality control features and to improve speeds.”

“As always, finding the right solutions for our customers’ needs is vital and after a rigorous selection process, we chose the BOBST EXPERTFOLD 110 folder-gluer. Its quick make-ready times, high precision and quality-centric features as well as production speeds convinced us to opt for this machine,” said Mr Reilley.

Cutting, folding and gluing expertise

Amongst the BOBST equipment already at Rondo-Pak’s disposal is an EXPERTCUT 106 PER installed in 2018 to give the company the latest in die-cutting capability with precision cutting, stripping and blanking all-in-one process allowing a throughput of up to 9,000 sheets/hour. Created with a very high level of automation, the EXPERTCUT offers flexibility for short runs and non-stop production for long runs. Changeovers are faster and simpler thanks to BOBST technologies such as CENTERLINE® and Quick-Lock devices, which eliminate errors and waste. Four camera registration allows for precise print-to-cut registration.

Meanwhile, the new EXPERTFOLD 110 A2, which was added in August of 2020, has increased efficiencies in folding and gluing. The versatile machine produces a variety of box styles in materials including paper, carton board and semi-rigid plastics. It runs at a maximum speed of 450 m/min - which means that every hour, over 150,000 straight-line pharma boxes will come off the line. Featuring BOBST’s unique SPEEDWAVE technology for crash-lock bottoms, Rondo-Pak has opted for one of the many devices that this exceedingly modular machine offers. All functions can be accessed via the CUBE3 control system, which can also store 5,000 job settings.

Together, the two machines have enabled Rondo-Pak to meet tighter lead times and produce a wider variety of box types. Having closely monitored their performance since the installation, Mr. Reilley could report that: “The equipment has performed as expected and moreover improved our efficiency. As a direct result of the increased throughput and reduced downtime, we have increased sales.”

Committed to service and support

As well as fault-free production, service and support also rank highly for Rondo-Pak as the company looks for reliability, dependability and commitment from its suppliers.

Mr. Reilley said, “Based on our many years of experience and history with BOBST, we know that their products are highly reliable. We also know that we can rely on their industry expertise and their strong commitment to service and support. Just as our customers trust Rondo-Pak with their needs and we support them in their journey from initial testing through to commercial supply, we put our trust in BOBST as our preferred partner, and I would highly recommend them.”

“The relationship we have built with Rondo-Pak over the years is second to none, and we are incredibly pleased to hear that the EXPERTCUT 106 PER die-cutter and the new EXPERTFOLD 110 folder-gluer have lived up to expectations and increased their sales,” said Brian Kentopp, Vice President, Business Unit Sheet Fed, Bobst North America. “Suppliers of packaging to the pharmaceutical and healthcare markets can rely on BOBST technology and expertise to give them a competitive edge with high-quality, fault-free packaging and industry-leading innovation.”

Bobst North America Inc, Parsippany, NJ, United States