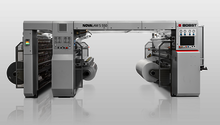

NOVALAM S 550 - Solventless laminator

Flexible and cost-effective production

A cost-effective, compact, solventless laminator, the NOVALAM S 550 is the perfect choice for converters. Incorporating a patented, automatic integrated washing system and the unique BOBST three column layout for maximum accessibility. With plug and play installation, the NOVALAM S 550 can be in production, 5 days after arrival at the customer's site. Every converters choice.

Versatile, flexible and ready to start

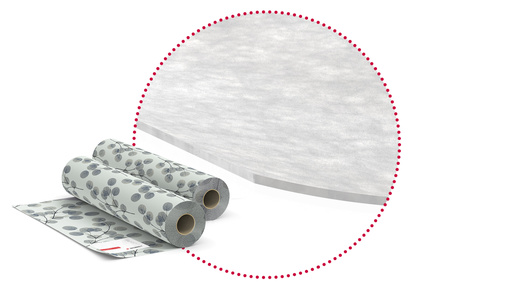

- Designed to handle a variety of substrates including thin alu-foil, metallized film and thin stretchable materials

- Equipped with sleeve transfer rollers for easy and fast job changeover

- Plug & play installation - no foundation needed, averages 1 week from arrival to production

- Standard web widths: 1030 - 1330 - 1530 mm. Other web widths available as option.

- Lamination speed up to 450 m/min

- 4.0 industry ready for post processing data.

Productivity & quality from short runs upwards

- Job changeovers completed in minutes without tools irrespective of configuration:

- on-board rotating cantilever system for sleeve type roll

- Pneumatic opening of metering roller for quick and easy adhesive disposal

- Automatic reel centering system reducing waste and start-up time:

- one touch winder setup

- quick fine tuning after web threading

- perfect reel alignment with linear encoder

- no telescopic effect

- Patented fully integrated automatic washing as standard supply

- 3-roller laminating nip for superior optical quality of coated adhesive

- 2 heated rolls for optimal process temperature control

- Independent setting of thermal regulation for coating unit and metering rolls.

Cost optimization and easy operation

- Patented design of long-life side retainers improves the laminator's efficiency and decreases costs

- Layout enabling full accessibility to the laminating nip for quality and process inspection without stopping the machine

- Adhesive mixer solutions for effective adhesive quantity control, matching production requirements

- Micrometric adjustment for perfect coating adhesive distribution

- Fully integrated HMI

- Intuitive, easy to read pictogram and commands for the setting, display and storage of individual job working parameters.

Download product literature