BOBST Platen Conditioning - Customer Testimonials

“After having the programme our production has increased and make-ready times have been reduced by 25-30 minutes”

Even with rigorous maintenance, the moisture content in cardboard tends to oxidise the beams, chase and platens of your Autoplaten® die-cutter. These deteriorate relentlessly, their metal components corroding and their surfaces becoming increasingly uneven. As a consequence, machine operators are required to spend increasing amounts of time preparing makeready sheets to compensate for parallelism faults in the platen. Your machine remains out of action for longer and you use huge quantities of makeready tape.

Armed with our knowledge of your needs, equipment and the market, we have designed an innovative, comprehensive, simple, and highly effective solution comprising of: a maintenance service – called Platen Conditioning – and a new range of products developed specifically to recondition your Autoplaten® die-cutter.

Faster make-readies and better quality

Edelmann Packaging India Pvt. Ltd. – Himachal Pradesh, India

Producing finished folding cartons for the beauty, healthcare and branded consumer goods markets, Edelmann’s Indian plant recently undertook a BOBST Platen Conditioning programme. “After having the programme our production has increased and make-ready times have been reduced by 25-30 minutes on each job,” says Assistant Manager Post-Press, Suresh Chandel.

The programme involves the reconditioning of the beams, support plates and chases of a BOBST die-cutter. This reduces both the amount of patch up and force required to produce a job. “We have seen an improvement in cutting since the Platen Conditioning, so we have faster make-readies and better quality,” says Mr Chandel.

Increased machine availability

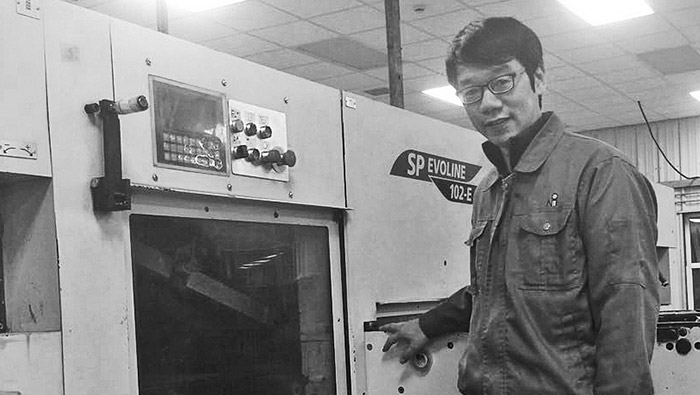

New Island Printing Co. - Shanghai, China

Established in Hong Kong over fifty years ago, the New Island Printing Company provides packaging and paper products both across China and to worldwide markets. As well as a production facility and headquarters in Hong Kong, the company has a large plant in nearby Dongguan and, since 1997, a Shanghai plant that employs 500 people. Product quality and machine availability are big issues for New Island, says Mr Chen Jinyan, Equipment Manager at the Shanghai plant. “When our local Bobst Services contact told us about the Platen Conditioning service, we were interested because quality is always important to us and so is anything that cuts make-ready time because it gives us more time to produce boxes.”

After getting BOBST to implement platen conditioning on the plant’s SP102 Evoline die-cutter, the result was a substantial reduction in the amount of patch-up required, reducing make-ready times by around 20%. “It is exactly what we hoped for,” says Mr Chen. “Cutting and creasing is more consistent, so quality is better, and we have extra availability on that machine to make more production.” A further benefit Mr Chen has seen is that less pressure is required to die-cut effectively. “We are using around 10% less cutting force on the conditioned machine, which will mean that our die-cutting tools will last longer.”

Back to the how it was.

Edelmann Poland Sp. z.o.o. – Pruszków, Poland.

Edelmann Poland manufactures premium packaging for the cosmetics and healthcare sectors, which demands quality and precision from its finishing processes. “One of the machines we use for this kind of production is our good old SP 102-BMA from 1980,” explains Karol Taborowicz, Head of Maintenance at the plant. Although in generally good condition, the hot foil stamper was starting to exhibit problems with temperature uniformity, which was leading to longer than normal set-up times. “Following discussions with the Services team at Bobst Polska, we decided to put the BMA thorough a Platen Conditioning program, along with some remedial work,” says Managing Director, Miłosz Glaser.

The Platen Conditioning procedure involves removing oxidation and contamination from the surface of the platen and from chases and cutting plates. “Thanks to Platen Conditioning the machine set-up is fast again,” says Mr. Taborowicz. “We no longer lose time adjusting and controlling temperature and stamping quality is once again consistent across the whole sheet.”

Miłosz Glaser, says that productivity on the hot foil stamper has significantly increased and costs have lowered, helping the plant remain competitive. “We will certainly be running Platen Conditioning programs on other machines now,” he adds.

Producing better products more quickly

Ueroku Printing Co., Ltd., Ikoma, Japan

Founded in 1932, Ueroku Printing supplies pharmaceutical and cosmetic packaging to customers throughout Japan. Always aiming to meet the high quality standards of these industries, and to improve its own profitability, the company recently implemented a BOBST Platen Conditioning programme on a BOBST SP 102 die-cutter, believing it would resolve several problems with the machine. “It used to cause a lot of defective boxes because of rust and staining, and it also took a long time to set,” recalls Mr. Inoue, Plant Manager at Ueroku Printing. “As a temporary measure to improve the setting time our operators had to zone patch.

“Mr. Inoue was very impressed with the Platen Conditioning program, which cleans the internal elements of the platen, along with the chase and cutting plate, using NSF registered cleaners and lubricants. “After implementing the Platen Conditioning programme we can operate production without any concern about staining. Also our operators can now makeready 20-30% quicker and use 20% less cutting pressure.”

Mr. Inoue says that as well as producing better products more quickly, the plant is now expecting its cutting tools to last longer thanks to the pressure reduction. “We are planning to implement Platen Conditioning on another machine shortly, because of the high performance of the first implementation,” he adds.

Immediate benefits

TCPL Packaging Ltd. - Haridwar, India

With plants in four cities across India, TCPL Packaging is one of India's largest manufacturers of printed folding cartons. The group’s two plants in Haridwar, 200 Km north-east of New Delhi manufacture both offset printed folding cartons and corrugated cartons.

Mr. D. Loganathan, Vice-President of TCPL Packaging Haridwar initially planned to try the Platen Conditioning Service on just two of the plant’s five machines. “But after seeing the benefits on the first two machines we decided to immediately proceed with the other three,” he explains. “The process is very good and it has reduced the time taken to make ready and the amount of patching we have to apply. We plan to do it regularly to maintain the condition of our machines.”

Shorter setup times, reduced tooling costs

Zerhusen Kartonagen GmbH – Damme, Germany

Producing a wide range of corrugated packaging – from simple boxes to litho-laminated cartons, e-retail packaging and triple wall - means that Zerhusen Kartonagen needs die-cutting equipment that offers consistent performance as well as high productivity. The plant’s eight-year old MASTERCUT 2.1 is normally at full capacity, around the clock, five or six days a week, meaning it operates for 5-6000 hours a year. Determined that the machine should keep up its high productivity, Maintenance Manager Ralf Düvel brought BOBST in to run a platen condition programme on the press.

"The results are rather better than we were expecting,” says Mr Düvel. "We were able to reduce the cutting pressure significantly. For example, today we are using 70 tonnes of stamping pressure on jobs that previously required 100 tonnes.” This reduction in pressure prolongs the life of the tools and so reduces tooling costs. “In addition, our machine operators now need to patch-up significantly less on most jobs. So overall we also have shorter setup times.”

Using specialist equipment and BOBST food-grade cleaning materials, the platen conditioning service removes the oxidation and corrosion that builds up in the platen’s cutting areas over time. “Given the experience using this service on the MASTERCUT, I think we will take the platen conditioning service for our SPO 160-Vision die-cutter as well," Mr. Düvel adds.

Higher Productivity

Zibo Ao Sheng Printing and Packaging Ltd. – Zibo, Shandong Province, China.

Ming Shun Gao, Equipment Manager at Zibo Ao Sheng Printing and Packaging, says that the BOBST Platen Conditioning service the plant undertook on its SP 102-E has helped optimize production and better maintain the die-cutter. “The reduction in make ready times especially helps us achieve higher productivity,” says Mr Gao.

The folding carton company employs 150 staff at its plant in Zibo, 400 km south of Beijing and Mr Gao says that Zibo Ai Sheng uses BOBST equipment and services because “it is a world-class brand with a good reputation.”

The Platen Conditioning on the SP 102-E removed the oxidation that builds up in die-cutter platen sections over time, reducing the need for patch-up, and hence speeding up make-ready. It also delivers other benefits, as Mr Gao explains. “This service helps us use less pressure to die-cut, which saves energy and makes the cutting tools last longer.”

Faster makereadies and fewer nicks.

Advance Paper Box Co. - Los Angeles, USA

As one of the longest established folding carton manufacturers in the USA, Advance Paper Box can handle even the most challenging packaging. But doing this efficiently means having equipment that is in the best possible condition, which is why the company recently used the Platen Conditioning Service from Bobst on three of its die-cutters. “The benefit has been that our makereadies are now much faster,” says Carlos Lopez, Production Manager at Advance Paper Box. “Depending on how many boxes are on the sheet, the time saving can be as much as 45, even 60, minutes. Plus the running speeds are higher and steadier because we don’t have all that corrosion from humidity inside the machine creating highs and lows in the platen.” The process has also helped the company maintain their high quality standards. “Another thing is that we use less nicks. We have a Serviform auto-bender that adds very precise nicks and we don’t have to add extra nicks to the die any more. So we get a better looking carton,” explains Mr. Lopez.

Repeat conditioning ensures optimal performance

DS Smith Packaging - Gent, Belgium

The DS Smith Packaging Division plant in Gent, Belgium, produces corrugated packaging for many of Europe’s best known brands. The plant has particular expertise in high precision die-cutting and, after carrying out a SMED (Single Minute Exchange of Die) analysis, Koen Verhaeghe, Business Improvement Manager at the plant, was convinced that set-up times could be improved by reducing the amount of time needed for adjusting makeready sheets - something that is a key benefit of the Bobst Platen Conditioning Service. “By having our machines conditioned, considerable time has been won back during the set up of new jobs as there is less taping needed on the makeready sheet. Quality wise, we can now run difficult jobs without problems and there are less issues with cracking. So the intervention did exactly what we needed.”

The plant has used the Bobst service on three platens of various sizes and generations, including an SPO1600. “The reason we did the Bobst SPO 1600 was because we sometimes have to swap die-cut jobs between machines. When the platens are in perfect condition, the negative effects of doing this are minimized.”

Mr. Verhaeghe sees the Bobst Platen Conditioning Service as an important part of the plant’s pro-active maintenance regime. “It is my strong believe that if you want to run a machine like a Ferrari, you have to maintain it like a Ferrari. By repeating the platen conditioning every one to two years, depending on the machine model, it makes sure that our machine availability and response to customers are at the best possible levels. Having the expertise of Bobst with us helps us to keep our machine in optimal condition.”

15 minutes slashed from makeready times

Tiong Tat Printing Industry SDN - Klang, Malaysia

As one of Malaysia’s fastest growing packaging companies, Tiong Tat Printing Industry has a large international customer base and a strong emphasis on ISO 9001.The company has been working with Bobst on initiatives to reduce the make ready times on their fleet of Autoplaten® die-cutters and was the first company in Malaysia to use the new Bobst Platen Conditioning Service, initially on its 2006 Bobst Speria 106 E. The resulting fifteen-minute saving on every make ready motivated the company to roll out the program across their four other Autoplatens®. Ms. Tan Jock Hong, Founder and Managing Director of Tiong Tat, says that in the very competitive markets it works in, this reduction in makeready times helps the company maintain competitiveness through higher productivity. “It has also helped us underscore our reputation as a fast and reliable supplier of high quality packaging,” she adds.