BOBST Grenchen celebrates 50 years of pioneering work in litho-laminating

In 1908, Joseph Bobst opened a workshop in Lausanne, Switzerland, and started to produce machines destined for the graphics industry. Today, the company he and his brothers founded has become one of the world’s leading suppliers of substrate processing, printing and converting equipment: BOBST.

The story of Joseph Bobst is a perfect example of the visionaries who begin developing their ideas in the corner of a small workshop and, based on the foundations of innovation and entrepreneurship, end by building a successful business. This spirit of innovation was also the cornerstone for the creation of a company specializing in litho-laminating, which has since become part of the Bobst Group. This year, that same company proudly marks its 50th anniversary.

Making corrugated board converting affordable

It all started with Karl Kramlehner, an employee in a corrugated board plant in Switzerland. At the time, the steam rollers used to produce the corrugated board were heated with steam. This system took up a considerable amount of space and required a dedicated steam boiler house. Back then, the equipment demanded significant investment, and the cost of such facilities made it impossible for small printing businesses to produce their own corrugated board for litho-lamination. But Karl Kramlehner had an idea and, in his own time, developed a space and money-saving gas-heated system that would replace the steam-heated equipment.

However, his project was met with skepticism and safety concerns. Struggling for support, his invention finally caught the attention of Armin Däster, an entrepreneur based in Grenchen, Switzerland, who was involved in the watch industry. Keen to promote the new system, Däster founded Asitrade in 1975 to support the project and organized the money and facilities necessary for this new machine to be built by a two-man team, which included Kramlehner. Däster even succeeded in securing a buyer for the prototype – the Micra WN5 – before it had produced a single sheet.

The world’s first in-line litho-laminator

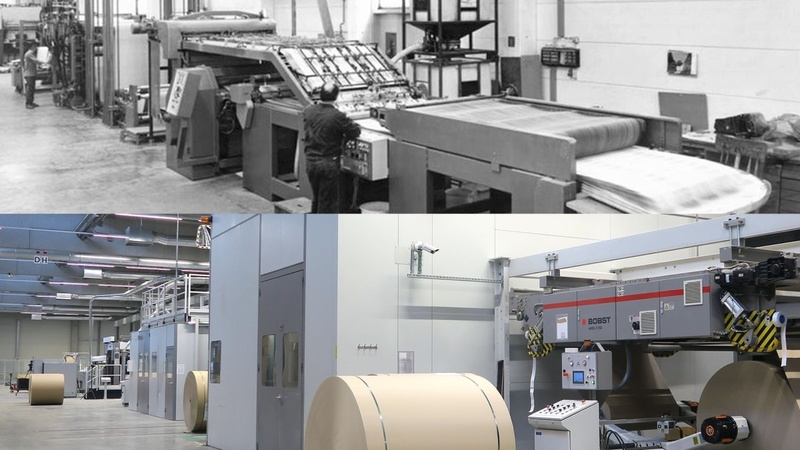

With the invention of Micra WN5, which was patented by Kramlehner in 1976, printers were able to fully integrate cardboard production into their business and command control of the whole litho-laminating process. The small business continued to innovate and, three years later, launched the world’s first sheet-to-web in-line laminator in 1978. This new machine could create single-face corrugated board, cut it into sheets, and laminate it with a printed sheet all in one seamless process. From what started as two distinct production processes, litho-laminating corrugated board soon became a much more efficient and affordable method.

Over the last 50 years, there has been a huge development in litho-lam machines and technology

In 1993, following company expansion, Asitrade became part of the Bobst Group and retained its own brand. Then, in 2012, when the Group moved to “One Group, One Brand”, Asitrade became Bobst Grenchen and its machines were rebranded as BOBST.

Daniel Müller, Site Manager in Grenchen, said: “We are a small team and very proud of our 50-year history and technical know-how. Our litho-laminators have evolved over the years and are among the most productive and versatile on the market. Although we already offer unique technologies, such as the POWER ALIGNER and the GAPRO glue applications system, we are continually working on improving our machines and driving forward Bobst Group’s vision of digitalization, connectivity, automation and sustainability.”

The latest novelty on the litho-laminators is the in-house central processing unit, which was developed by a handful of specialists in Grenchen. “This has been a significant step for us to be able to gain independence from external suppliers, improve machine control and open the door to the BOBST Connect platform,” added Müller.

Looking into the future

For Marco Lideo, Head of Product Line LADSF ETERNA DIGITAL, the team in Grenchen is an asset for the Group: “We are very proud of our litho-laminator portfolio. The site in Grenchen may be relatively small, but we have a great pool of specialists there who bring irreplaceable expertise into the company.”

The trend for more attractive and high-quality packaging has shown that litho-laminating may not be a brand-new technique, but that it remains high in value. “Litho-laminating remains a preferred method for combining premium graphics with durable corrugated packaging,” says Lideo. “Our machines are the result of a solid 50-year experience in litho-laminating and brand-new technologies transforming the converting industry.”

As such, the integration of a new central processing unit has been a huge step forward toward the digital and connected future that BOBST is currently implementing across its Group products and services. “The desire for change and the courage to tread new paths were the building stones for our success. We certainly want to live up to that legacy,” concludes Lideo.

BOBST