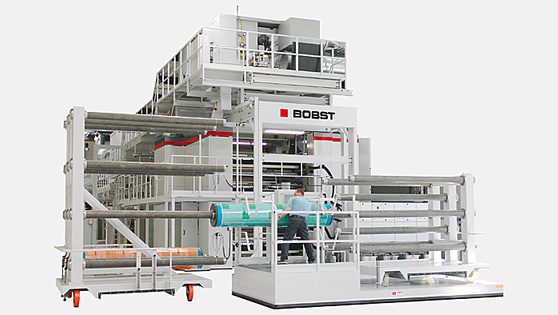

MASTER CI 90SIX - Flexo press

Large formats. User-friendly handling

- Auxiliary equipment like cylinder cart and transfer station with lifting table is used for the fast and ergonomic handling of the large change-over parts. The cylinder cart is coupled to a partially automated underfloor rail system between press and transfer station. All changeover parts are extremely light and the print qualities of one such material, carbon fibre, are superior to all known materials.

Precision impression and register adjustments

- Precision adjustments for premium print quality through servo drive technology and sophisticated mechanics: via portable control panel, the print units can be adjusted with a resolution of 1.0 micron (0.00004") and the register with a resolution of 0.01 mm (0.0004").

Solid design meets ease of operation

- Single handed, easy opening of the generously proportioned, counter balanced bearings of plate cylinders and anilox rolls. Air pistons slide the cast iron bearing blocks – an effortless process performed within seconds.

Options for ultimate productivity

- Options like smartGPS™, stack type downstream units, the unique EXTENSION module which extends the standard repeat of 2'060 mm up to 3'500 mm, and flexible logistic systems for accelerating the changeover process ensure a degree of flexibility and equipment availability unparalleled for large format preprint applications.

Cantilever sleeve system for fastest change-overs

- The changeover is facilitated by a cylinder cart, which is aligned exactly to the print stand by means of a positioning system. The Access system makes it possible to change-over non-operational print units, even while the machine is running. Thus downtime is reduced to a minimum and the advantages of the sleeve technology are clearly evident.