Robotic solutions

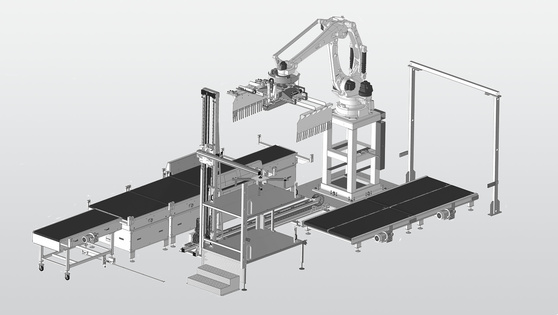

ROBOLOADER Folding-Gluing (FG)

With ROBOLOADER FG, the transfer of blank piles to the feeding area is completely automated. The robot ensures regular and consistent feeding at top machine speeds, enabling optimal production line productivity. It is easy to operate and quickly setup, reduces the workload, prevents repetitive strain injury (RSI) and the need for constant operator presence.

ROBOLOADER FG for standard formats can be adapted to irregular box formats and has a second robot stabilizing the stacks during pickup.

The ROBOLOADER FG for e-commerce boxes is a simple solution for square e-commerce boxes with a gripper capacity of 550 mm and speeds of up to 96’000 boxes per hour. This e-commerce version has been created to ensure top speed for the folding and gluing of simple boxes.

ROBOLOADER Die-Cutting (DC) DF

ROBOLOADER DC DF for the direct feeding (DF) of die-cutters, lifts and places batches of a great variety of sheets, from microflute to triple wall, directly into the feeder. It has an integrated wall for separating, centering and a back stop for the perfect positioning of the stacks. A 6-axis robot with mechanical gripper provides the capability to overturn the batches.

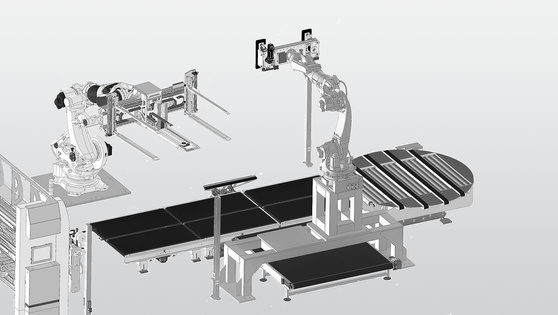

ROBOLOADER Die-Cutting (DC) SF

ROBOLOADER DC SF feeds batches onto a conveyor belt for continuous shingle feeding (SF) into the die-cutter. It handles batches of a great variety of sheets, from microflute to triple wall. A centering device ensures precise positioning on the feeding belt. A 6-axis robot with mechanical gripper provides the capability to overturn the batches.

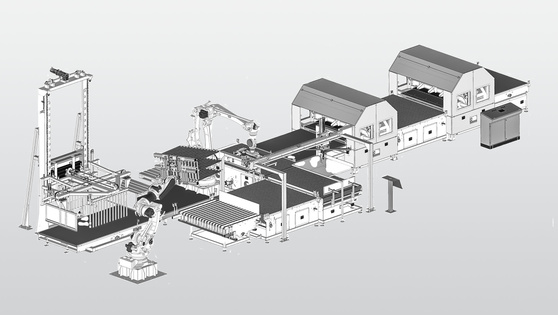

ROBOLOADER Flexo printing & folding-gluing (FFG) DF

ROBOLOADER FFG DF for the direct feeding (DF) of flexo folder-gluers, lifts and places batches of a great variety of sheets, from microflute to double wall, directly into the feeder. ROBOLOADER FFG DF has an integrated wall for separating, centering and a back stop for the perfect positioning of the stacks. A 6-axis robot with mechanical gripper provides the capability to overturn the batches. The layout can be adapted to enable the side entry of the pile.

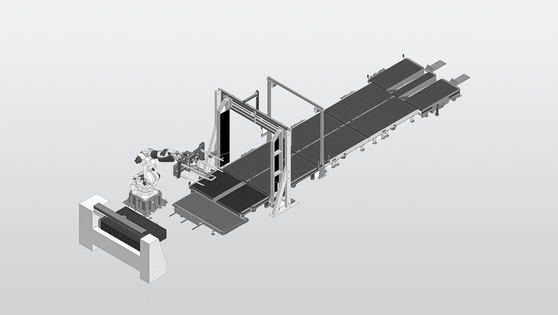

ROBOLAODER Flexo Folding-Gluing (FFG) SF

ROBOLOADER FFG SF feeds batches onto a conveyor belt for continuous shingle feeding (SF). It handles batches of a great variety of sheets, from microflute to double wall. An integrated buffer allows to stock and continually release sheets to ensure highest feeding speeds. A centering device ensures precise positioning on the feeding belt. A 6-axis robot with mechanical gripper provides the capability to overturn the batches for top/bottom printing.

ROBOPALLETIZER Folding-Gluing (FG)

ROBOPALLETIZER FG has a hybrid gripper, with a vacuum gripper for small bundles and a mechanical gripper for unstrapped boxes and bigger bundles. It gives great flexibility for stacking patterns and tie-sheet positioning to get perfectly squared stacks, guaranteeing box quality and transport safety.

It is possible to combine two robots for top speeds. ROBOPALLETIZER FG can be connected to SPEEDPACK and its banding/strapping solutions (ATS, Signode) for automated robot settings.

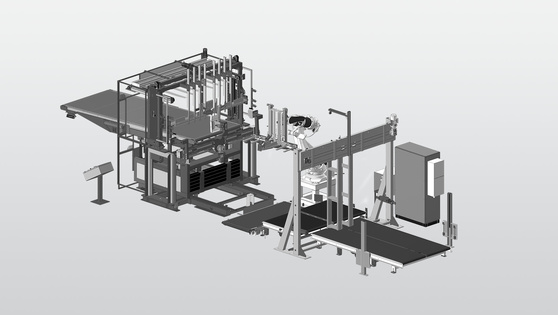

ROBOPALLETIZER Die-Cutting (DC)

ROBOPALLETIZER DC is an excellent breaking and palletizing solution for mid-range productivity die-cutting lines. The full version of ROBOPALLETIZER DC includes BUNDLE BREAKER and double layer gripper for more productivity.

Two BUNDLE BREAKERS separate the bundles, before the layers are arranged and palletized with a 6-axels robot which can double the layers and turn the batches over. Highly flexible, with an action range of almost 3 m radius and 300 kg workload, it offers a wide range of possibilities. The BUNDLE BREAKER can also be installed individually (stand alone).

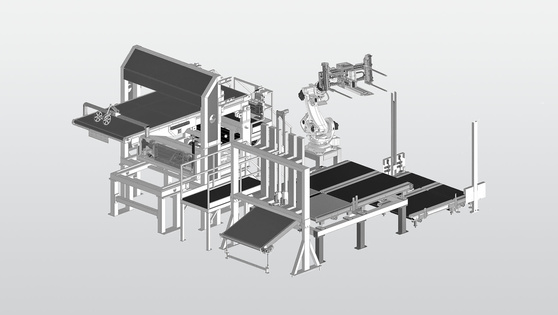

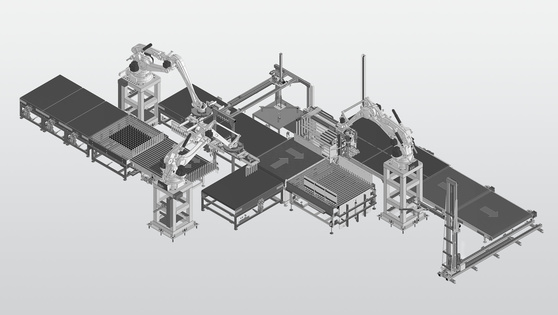

ROBOPALLETIZER Flexo Folding-Gluing (FFG)

With ROBOPALLETIZER FFG, one robot prepares and superposes layers to create double layers, while the other robot builds up the piles. Tie sheets and bottom sheets can be inserted with independent systems between the two robots to optimize the palletization.

Different solutions (MASTER, EXPERT and VISION) allow to adapt the footprint and achieve different levels of performance according to customer needs.