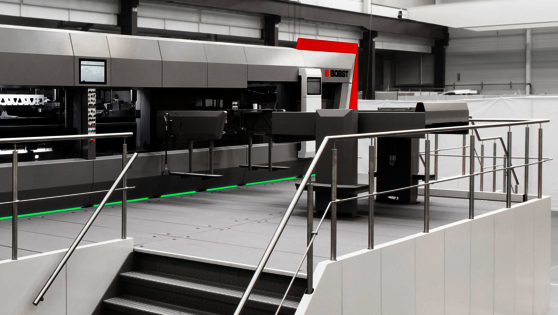

MASTERCUT 1.65 PER - Autoplaten® die-cutter

SMART FEEDER 3

- Top feeding system with suction units and wide transport belts for gentle feeding of sensitive substrates

- Fully automated pile positioning and sheet synchronisation for smooth and precise sheet entry, cutting feed errors and providing continous and stop-free production

- Feeding table with dedicated pressing device, tailored for careful processing of warped materials

- Delicate feeding and processing ensures top blank quality and reduces waste

POWER REGISTER 3

- BOBST technology, especially adapted for converting corrugated and litholaminated board

- Guarantees high-precision die-cutting results with folding carton register accuracy

- Contactless sheet registration preserves perfect sheet integrity

- Optical register reads either sheet edge or printed marks, allowing flexibility in lay-outs and substrate choice

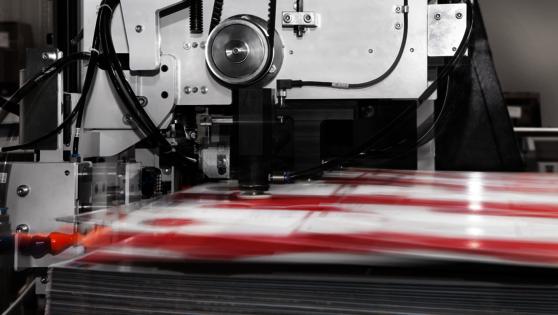

Platen section

- Powerful die-cutting force with low pressure on the sheet, cutting robust substrates and delicate materials equally well

- Automatic cutting force adjustment, increasing tool longevity

- Reductions in makeready time and set-up time with CENTERLINE and automatic supporting plate locking

- Optional TooLink allows recipe management automation, drastically reducing setup times for repeat jobs

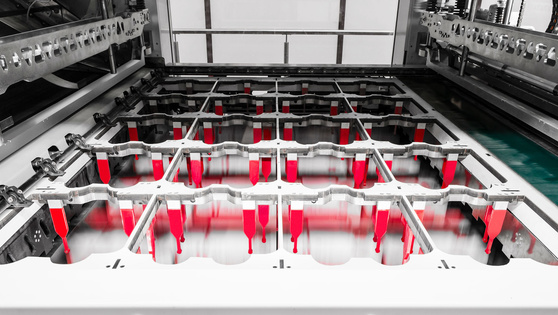

Stripping section

- Compatible with folding carton and corrugated board tools, for maximum flexibility

- A dynamic cradles locking device prevents wrong blanks from being processed, preserving tooling and ensuring product quality

- Fast and easy removal of a die-cut sampling sheet for quality check

- Easy access and quick setting for more uptime and operator-friendly handling

Seamless changeovers

- Tool compatibility allows swift equipment changes between folding carton, corrugated and litho-laminated board jobs

- Operator-friendly step-by-step setup via HMI SPHERE

- MATIC positioning of all feeder, platen press, waste stripping and delivery settings, saving time and guaranteeing maximum precision

- Up to 15 minutes savings on setup time for repeat jobs with TooLink

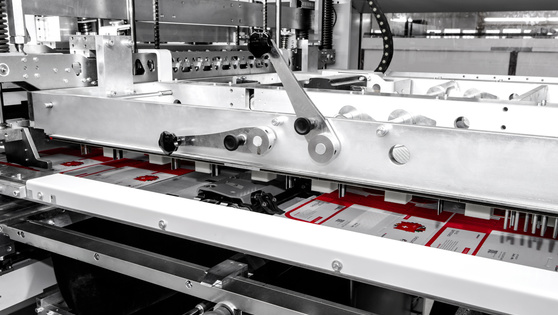

Blanking and delivery

- Single cut, double cut or full sheet delivery provide maximum flexibility

- Adjustable non-stop rack enables the delivery of perfectly counted batches

- Automatic jam detection system and dynamic waste ejection guarantee perfect stacking of impeccable blanks

- Continous and stop-free delivery of batches, ready for downstream processing

- Optional shredder system for automatic removal of blanking waste

Maximum level of automation

- Fully automated die-cutter for extreme precision, maximum efficiency and reduced workload

- Can be combined with BOBST peripherals to form a complete production line, fully integrated into the company’s logistics

- MATIC positioning for board dimensions and substrate thickness from feeder to delivery, allowing quick setups

- HMI SPHERE with intuitive navigation, stores up to 5,000 jobs, considerably shortening makereadies

- Optional TooLink allows recipe management automation, drastically reducing setup times for repeat jobs