VISIONCUT 1.6 | 1.6 PR - Autoplaten® die-cutter

Bottom feeder

- Perfect sheet alignment with height adjustable rear sheet support

- Handles all types of materials, from microflute to double-wall with ease thanks to vacuum suction plate

- “Air Knife” under the gauge for flawless sheet introduction and fewer stops

- Optional POWER REGISTER for perfect, contactless print-to-cut sheet registration

Platen section

- Improved platen construction resulting in shorter make-ready times and reduction in cutting force needed

- Ergonomic, precise and perfectly parallel cutting force adjustment using a single foot wheel

- Substantially increased machine up-time and tool life

- User-friendly CUBE interface

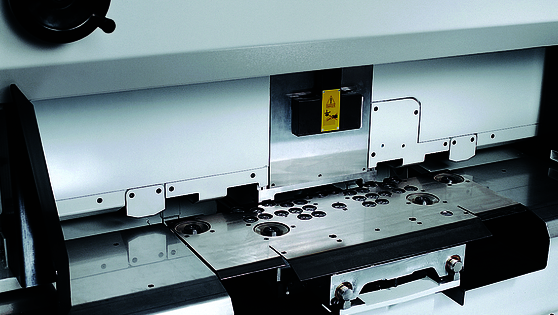

Double cam gripper bar advance

- Accelerates and decelerates sheets in the smoothest way possible

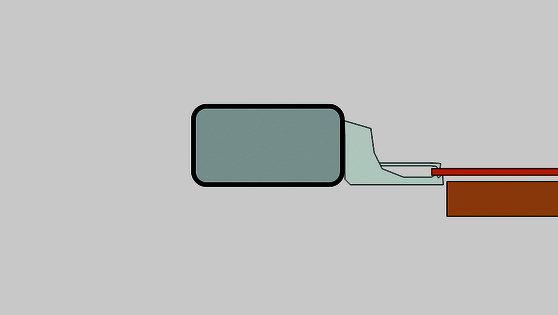

- The new lower gripper position further enhances flat sheet travel, reducing stress on the sheet as it travels through the machine and allowing for higher production speeds

- Smaller nicks for improved finished product quality

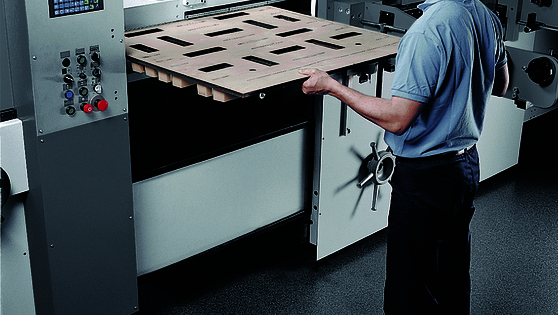

Job changeovers

- BOBST Centerline® system for fast and highly precise alignment of die-cutting, stripping and delivery tooling

- Simple machine for intuitive, quick and easy set-up and changeovers

- Optional chase loader for even speedier and more ergonomic job preparation

Stripping station

- Precise ejection of even the smallest waste from the most complex layouts

- Dynamic upper stripping frame with fixed central stripping board, resulting in no vertical movement of the sheet and the most perfect stripping result

- Large windows for most ease of access and faster set-ups

Delivery

- Perfectly stacked and aligned batches of up to 200 mm in height even at top running speeds

- Adjustable delivery frames for optimal sheet reception

- Straight lateral support guides for perfect sheet release and stacking

- Male-female ejection tool for accurate removal of front waste, even at full speed