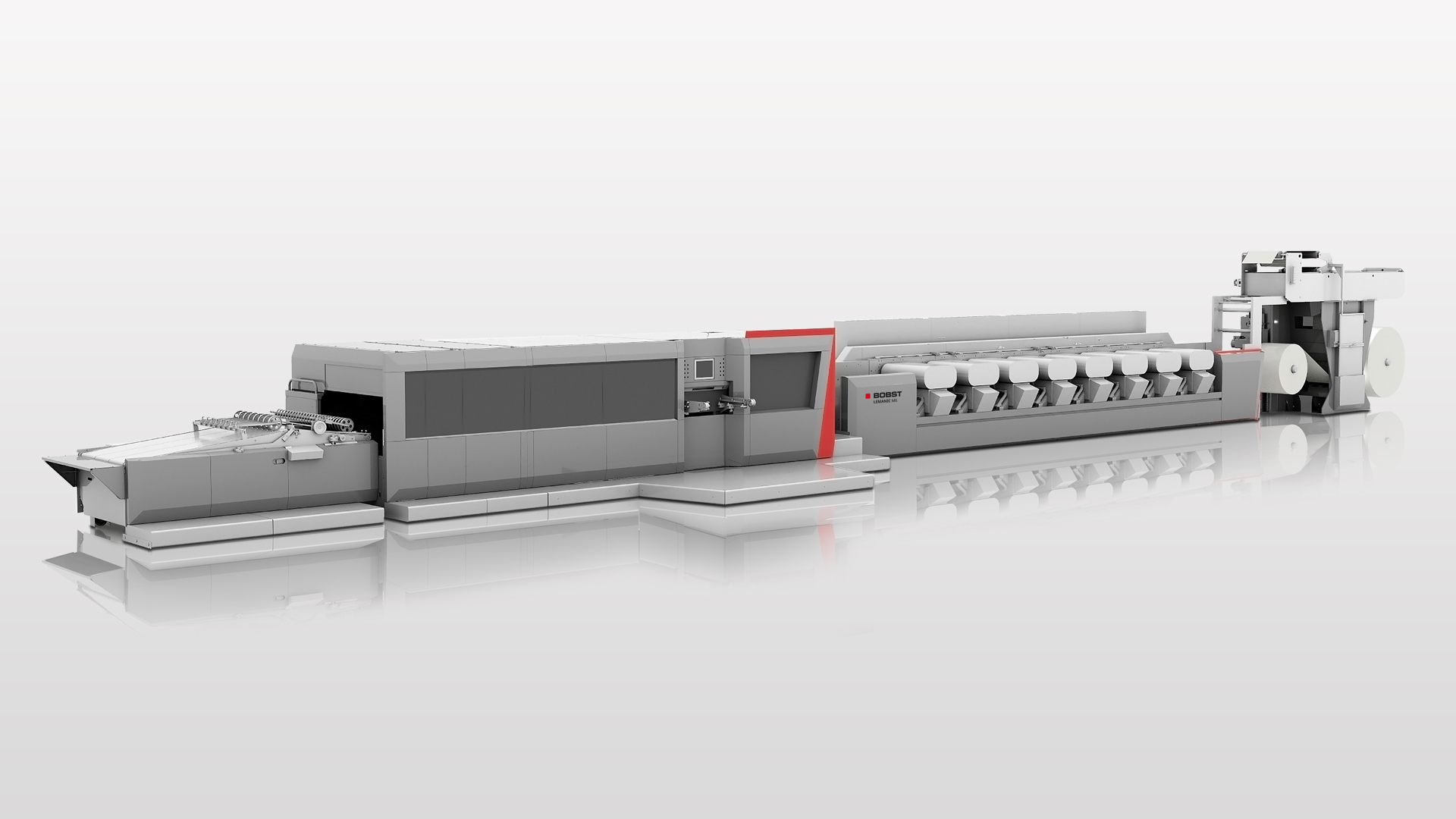

LEMANIC® M6 - Flexo press

The LEMANIC® M6 produces high quality finished blanks in a single inline machine pass. This innovative machine leverages the reputed BOBST's inline flexo printing technology and the LEMANIC® converting expertise into a unique production line.

BOBST innovations in flexo technology such as smartSet or oneECG Extended Color Gamut printing deliver unprecedented workflow efficiency, color consistency and repeatability. This is complemented by the press' flexibility to use UV and water-based inks, as well as numerous inline embellishments possibilities.

The line's printing and converting assets, including multiple post-print solutions such as in-line flat-bed or rotary converting, brings high agility to meet brand owners' requirements. It also offers innovative and diversified solutions to the general folding carton market targeting short & medium production volumes.

Unprecedented agility

- The LEMANIC® M6 modular and evolutive configuration flexibility allows the progressive integration of the latest processes to match the changing market trends:

- handles a wide range of substrates including paper, cartonboard, PE coated and metallized board up to 400gsm

- UV or water-based printing for food-safe packaging applications

- countless in-line process combinations for innovative and sophisticated packaging solutions, including lamination, cold-foil, back printing and gravure printing

- Complex graphics features can be processed for food and non-food packaging.

Exceptional productivity

- V-Flower print head concept for the automatic exchange of print cylinders enables 1 minute print job changes without stopping the press

- Speed up to 200 m/min

- Printed and converted folding cartons delivered in less than a minute in a single machine pass

- Order to shipment cycles down to 48 hours

- Just In Time production reaching 6000 tons per year for small and medium sized cartons

- Up to twice production capacity on same shop floor surface compared to offset printing.

Advanced sustainability with cost savings

- The LEMANIC® M6 inline machine optimizes productivity and waste efficiency, thanks to its single-pass concept

- In-line converting allows interlocked die-cutting layouts with minimized waste levels

- In-house integrated register control system guarantees tight register accuracy at all production speeds ensuring minimum waste run after run

- The reduced footprint enhances shop-floor efficiency

- Water-based ink printing addressing today's ever growing sustainability requirements.

Extended capabilities for product diversification

- Full range of in-line embellishments and custom solutions:

- tactile effects

- hot foil stamping and holograms

- cold foil applications

- inline UV lamination

- security printing.