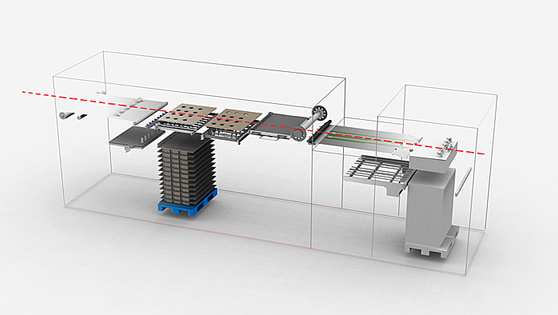

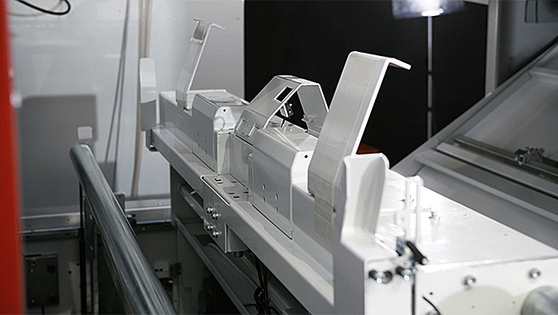

VISIONLINE 1.6 - Production line

Centerline®

Guaranteeing fast and precise tool positioning, Centerline® delivers quick machine set-ups, increased up-time, and superb finished product quality. Unique to BOBST, the patented Centerline® tool alignment system is found in every one of its flat bed die-cutters and hot foil stampers. By using a fixed master reference, which all movable elements of the machine reference to, tools can be pre-aligned, off-machine.

Changing of plates

Plates are easily located and precisely positioned by a centering system. Two plate lockups are provided as a combination: the BOBST 'Fix' system and the Matthews fast lock.

Chase loader

Wide, low, work platform with chase loader for preparation of the next job during production.

Controls - CUBE

The CUBE device (Control Unit BOBST Electronic) controls all functions of the machine and allows very precise setting of the print register. The rotation of each printing unit can be independently indexed following a programmed stop. This facility ensures that after a printing plate change or ink wash-up your print is in register from the first sheet.

Delivery

- Mobile delivery frame sets

- Straight lateral guides support

- Gripper opener device (optional)

- Closed-loop batch delivery program

- High pile 1'200 mm (optional)

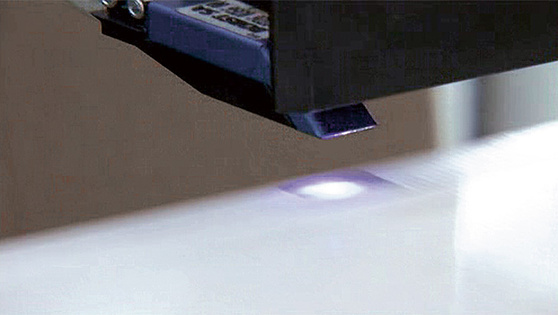

Driers

Driers for fast color fixing. Duo-Technik UV or hot air systems guarantee the drying of ink between colors, avoiding smudging (option).

Easy quality control

A dedicated unit collects sheets needed for quality checks during production, as well as those ejected as non-conforming by the Registron® system or iQ300.

Feeder equipment

Lateral joggers at the feeder with optional blower and lateral rear sheet guides. Includes removable, adjustable backing roll.

Front waste

The gripper margin removal device is easily introduced from outside of the machine. It is possible to work without gripper margin (option).

Inking

Simple system with a minimum of ink in circulation. Inking with two rollers, rubber and anilox, with movable reverse angle doctor blade. This enables the operator to adjust the volume of ink applied in response to the quality of the substrate.

Intermediate table

Intermediate table places a batch on stand-by to ensure high-speed workflow during loading of the next pile (option).

Non-stop production

Buffer feeder ensures no workflow interruption. Photocell barriers enabling easy access photocell barriers.

Pallet centering

- Piles automatically loaded and centered

- Synchronized lift process

- Rear jogging and blowing system

Pallet evacuation

During pallet evacuation and the loading of the next pile, the intermediate table places a layer on stand-by to ensure the high-speed flow of the layer of sheets into the feeder.

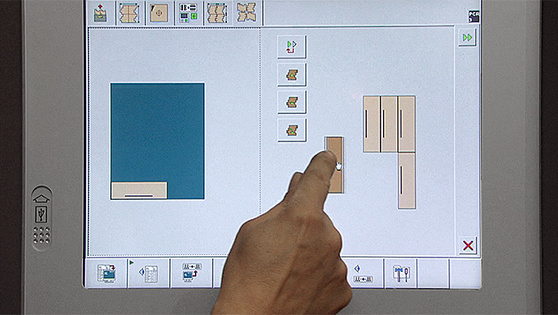

Palletization programming

The intuitive palletization programming interface, using drag & drop, allows for automatic management of layer arrangement.

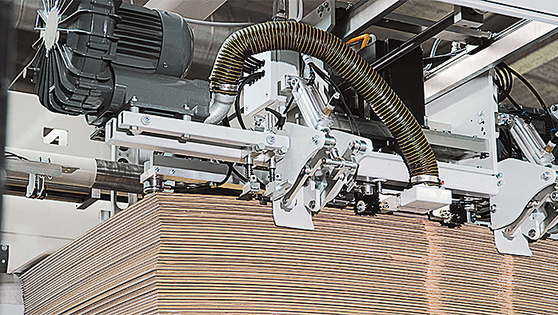

Perfect finished pile quality

Perfectly aligned piles, vital for packaging machines, are produced by alignment on all four sides. Boxes are not marked due to the elimination of friction on delivery of the layer. The insertion of a tie-sheet before palletization ensures perfect stability of the pile during transport.

Platen

- Improved BOBST platen construction, including 4 connecting rods linking the crankshaft to the 4 toggles that support the mobile platen

- Very high cutting force

- Parallel adjustment of the cutting force by a single foot wheel

- User-friendly CUBE interface

Power Register

Sheet edge and/or printed mark reading infeed system that guarantees incredible print to cut register accuracy.

Production inspection

Tray for inspection of sheets during production, and ejection of sheets detected as out of register by the Registron® system.

Rear sheet support

Rear sheet support with lateral and rear jogging for perfect sheet alignment. Adjustable sheet backing roll. Rear batch lifter for easy grip in the event of a jam.

Safety claws

The operators’ safety is ensured by a system of claws which are introduced into the chain system at each machine stop or at the opening of a guard.

Sheet transport

The platen diecutting presses are fitted with the latest electronic and mechanical advances in terms of sheet transport. Every movement has been engineered to obtain optimum transport, from the feeder to the delivery station, with smooth acceleration and deceleration of sheets. The lower gripper position enables much flatter sheet travel through the machine and the stresses on the contact points are greatly reduced.

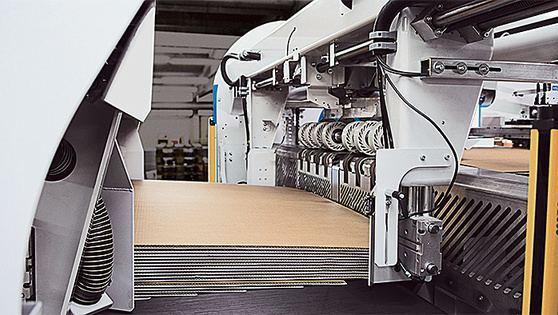

Sheet transport

Corrugated sheets are transported through the printing press by driven rollers and vacuum air. This vacuum transport system brings many advantages:

- No other contact with the printed surface

- High printing precision

- Quick running

- Easy operation thanks to room between groups

Stripping station

Stripping station Featuring:

- Gripper opening for quality control

- Waste pinching system

- Precise ejection of small waste using male-female stripping tool

- No vertical movement of the sheet

- Easy access

- Mobile upper stripping frame

Stream of sheets

Shingled stream of sheets prevents pressure differences on the suction plate.

Suction plate

The suction plate ensures the precise introduction of all qualities of board from microflute to double-double.