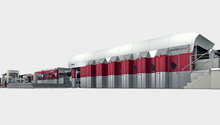

MASTERLINE 1.7 | 2.1 - Production line

As brand owners demand ever higher die-cutting and print quality from their corrugated packaging suppliers, achieving both, while retaining a profit margin, has become increasingly important for box makers. That’s where MASTERLINE comes in.

In its full configuration, a MASTERLINE production system consists of a loader, up to eight MASTERFLEX-HD print units, a MASTERCUT 1.7 | 2.1 flatbed die-cutter, a blank separator with automatic bundle arrangement, and a palletizer. Using MASTERLINE, just two operators, in two shifts, can process over 20 million square meters of board a year.

Producing finished packaging in a single pass, just-in-time, without the need for intermediate stock, MASTERLINE offers high volume, high quality throughput at the lowest possible production cost.