NOVAFFG

Essential technology

- Accurate feeding from E-flute to double wall

- Maintenance cost reduced and optimized, few wear parts

User-friendly operations

- Easy operation, 1st sheet sellable

- Intuitive human machine interface

- Full control of your machine

- Color touch screen with graphic mode, no text

Lean footprint

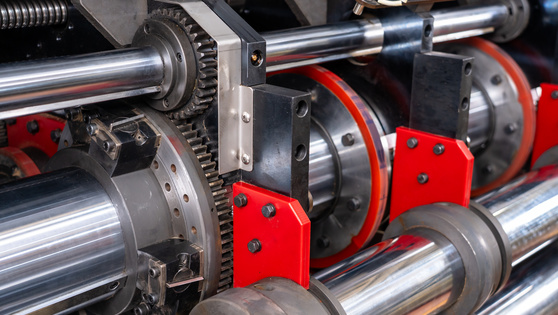

- Gear train solution from feeder to die-cutter

- Vacuum power controlled automatically according to board dimensions

- Compact layout

Set up time optimized

Slotter

- Automated and unlimited glue lap extension: setting without operator intervention

Top die-cutter with Posilock®

- Quick positioning & locking system

- Short die-cut tool change in less than 2 minutes

Accurate and consistent folding quality

Slotter

- Robust slotter with 4 pairs of shafts including 3 steps of scoring

Folder-Gluer

- Consistent Gap by means of folding gauging roller shape according to folding angle

- Minimized Fishtailing by means of lower folding belts with independent motorization