Folding-gluing process

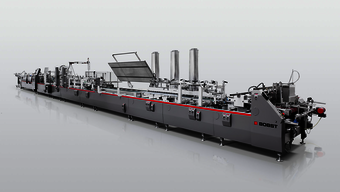

Having designed and manufactured folder-gluer lines since 1942, BOBST has a wealth of experience in this field. From our original machine, the PCR 382, right through to today’s high productivity models, we have utilized the know-how of our people, the input of users, and extensive research and development, to produce equipment which constantly advances what can be achieved using this inline process.

Each folder-gluer and peripheral in the BOBST range is designed to deliver versatile performance, high product quality, and excellent reliability. The modular nature of BOBST folder-gluer lines mean that they are available in several versions, allowing the production of simple to highly complex cartons, in tiny to large sizes, of short to long run lengths, with varying levels of automation.

Folding and gluing process

In essence, the folding and gluing process transforms a piece of flat material into a finished product such as a box, envelope, or promotional item. This is achieved by folding the blank along pre-creased lines and applying the adhesive that will hold the product together.

Folder-gluers are suitable for processing a wide range of materials including solid board, plastics, metalized varnished boards, litho-laminates, micro-flutes, and corrugated board. Their use is seen mainly in the packaging industry where they transform flat blanks into straight-line, crash-lock bottom, or multi-point boxes.

In the carton sector of the packaging industry they are often called specialty gluers or carton gluers. Folder and gluers are also used outside of the packaging sector by businesses such as envelope manufacturers and commercial printers.

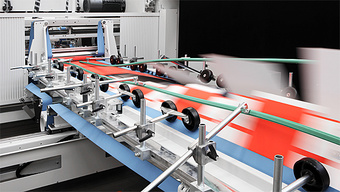

As a die-cut and creased blank passes through a folder-gluer, a selection of specially positioned guides, rotary hooks, and other devices fold its panels to their required positions while adhesive systems apply cold glue or hot-melt adhesive to appropriate locations.

The folded and glued blank will then be placed under pressure for the adhesive to cure as it is transferred to the delivery. Highly sophisticated control systems track the blank during its transformation and, in conjunction with quality assurance equipment, will eject any product that does not conform to pre-determined criteria.

Folder-gluers

A BOBST folder gluer is a modular machine which will consist of a number of different sections, depending on the application. These may include:

- Feeder: ensuring the precise feeding of the blank is vital for accurate processing. Various designs of feeder help process specific materials or products more effectively

- Prebreakers: these pre-break the creases of cartons for their easier processing on automatic filling lines

- Crash-lock module: using conventional or hook-free technology this unit folds the base flaps of automatic crash-lock bottom cartons

- GYROBOX unit: for rotating blanks at full line speed, allowing single pass processing of complex products

- Combifolders or 4/6 corner devices: rotating folding hooks that fold the flaps of multi-point cartons

- Folding section: for progressive folding of the final fold

- Transfer section: ejects non-conforming cartons and shingles cartons for delivery

- Delivery section: applies pressure to the box stream to allow good adhesive bonding

Folder-gluer machines may be augmented by a range of peripheral devices such as loaders/batch inverters, special feeders, packers, and robot palletizers.

Additional operations

Along with being a high speed and cost effective means of producing a range of products, modern folder-gluer lines do more than just fold and glue. Additional inline processes that a folder-gluer can be configured to carry out may include:

- Applying tip-ons, film windows, or Braille embossing

- Joining two or three blanks together to create one larger carton

- Checking the quality of Braille embossing, print, or gluing on the product

- Packing or bundling the product ready for onward transportation

BOBST expertise and knowledge

The BOBST range of folding and gluing equipment offers box makers, finishers, and commercial printers the versatility and performance they need to maintain profitability in today’s tough markets. From complete folder-gluer lines to specialized add-on modules, every piece of BOBST equipment is designed to help users cut make-ready times, maximize speeds, and significantly boost in-plant efficiencies.

But this is only part of the story, because time after time BOBST products provide users with an opportunity to open up lucrative new markets, along with the ability to sell additional products to existing customers.