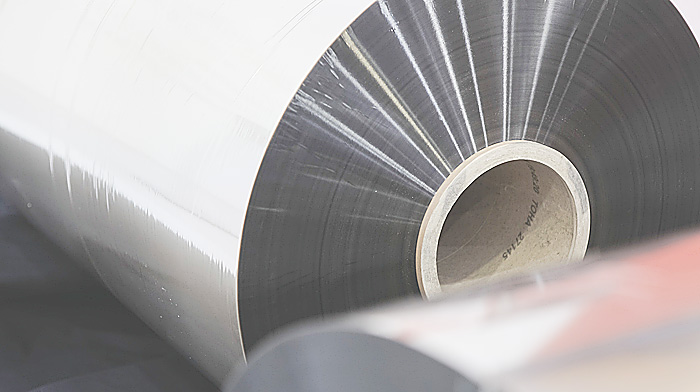

AlOx Conversion

Integrated Solution to Protect AlOx Film During Conversion

Established AlOx coating process

- Simple and efficient AlOx process well-established in the market

- Excellent coating uniformity and transparency

- Recyclable: ideal for converters looking to contribute to a circular economy.

Process Know-how from Single Supplier

- Incorporates application of off-line topcoat

- Protects and enhances barrier during conventional conversion processes

- Faster time to market from day one

- Outstanding barrier performance and flex crack resistance.

Maximum productivity

- Works at maximum operating speeds with no compromise to performance

- Relatively low capital investment

- Low running costs

- Game changer in the packaging industry.