VISION K5 HS - Vacuum metallizer

High performance

- The new design evaporation source has a 100 mm full staggered ceramic boat arrangement providing excellent coating uniformity. The machine also has a lower aluminium consumption and improved boat life. With access to both sides of the source, a simpler wire feed design and reduced maintenance. The addition of a pneumatically activated shutter provides faster response times.

Metallizing

- Largest coating window in the industry which along with the new Ø 700 mm drum improves aluminium collection efficiency.

High productivity

- The VISION K5 HS has faster coating speeds (860 m/min at 2.2 OD) with a 20-minute improvement in cycle time. The Shutter on the Hinged Shield makes the cleaning process easier. Diffusion pump lids on the vessel wall also means reduced cleaning and the compact vacuum pumping group results in the smallest machine footprint in the industry.

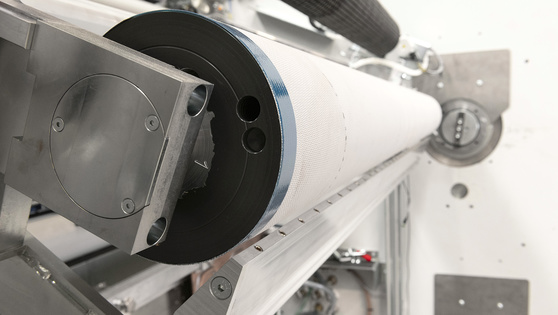

Improved winding

- The renowned BOBST winding mechanism incorporates a 6-drive system giving 3 independent tension control zones with true tension control for virtually wrinkle-free film. With minimum roller contact, the VISION K5 HS has been designed for careful handling of heat-sensitive substrates such as PE.