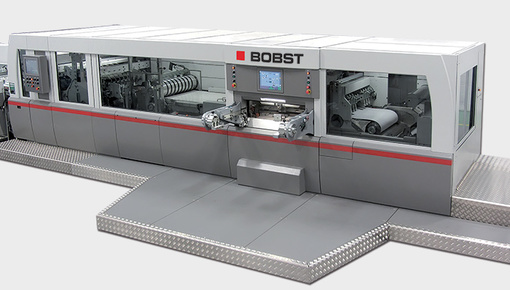

Line components

By bringing together over seventy years of printing experience with an equal length of time at the forefront of conversion technology, BOBST is able to offer web-fed converting lines that lead the way in accuracy and performance. These lines appeal to carton manufacturers who split their web-fed production process into two parts: first printing and rewinding, then taking the pre-printed reels and converting them offline.

The approach allows for a rapid response to market changes and can help maximize the use of plant capacity and installed equipment. By constantly developing new technology for offline conversion, from high speed die-cutters to remote diagnostics, BOBST is able to offer end users equipment that keeps them ahead of their competitors.

LEMANIC® RDC 67 D | RDC 82 D - Rotary die-cutter

Cost effective rotary die-cutting

LEMANIC® DRIVE - Rotary die-cutter

High speed rotary die-cutting

LEMANIC® FCC 82 HS - Flatbed cutter-creaser

Be competitive on short runs

LEMANIC® SEPARATOR

Optimise the production workflow

LEMANIC® SLEEVEXPERT 85 - Sleeve-type embossing unit

Embossing gives structure to packaging

LEMANIC® SPEEDFLOW - Delivery solutions

Get the full control of your production output

LEMANIC® SHEETER

Flexibility in post-print process

REWINDER

Add process flexibility

Registron® iQ 400 - Quality control system

100% inspection of 100% of the web 100% of the time (no sampling)

Registron® S 6100 - Integrated Register control system

Inline register control