Converting

Tooling and equipment that enhances and improves converter capabilities

Today's packaging industry demands ever-increasing accuracy, complexity, and turnaround-speed. Converters require precise, reliable and powerful tooling and equipment - to minimize changeover and downtime, and maximize production efficiency, while delivering outstanding reliability and packaging quality for customers.

BOBST offers an industry-leading range of equipment and consumables covering all cutting, stripping and blanking stations, and enabling converters to be more responsive, accurate, productive and competitive.

Cutting station

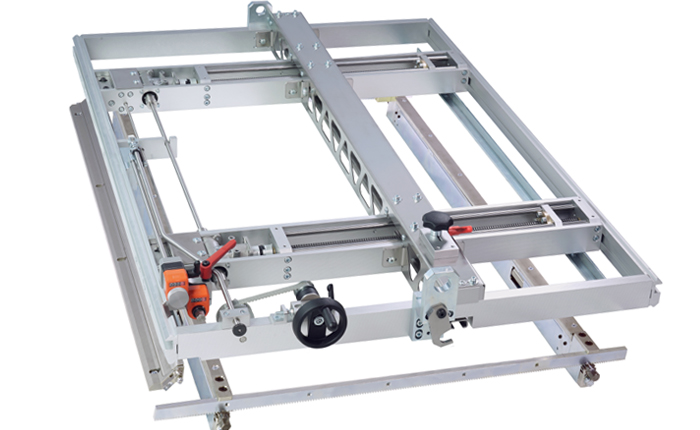

Hard-working cutting stations need durable, easy-to-install die-cutting tools and consumables. BOBST's cutting station products fit all BOBST machines and enable the streamlining of maintenance and changeover operations. Featuring innovative quicklock designs that eliminate time-consuming screwing, they save converters time and enable maximum performance.

Easy Locker

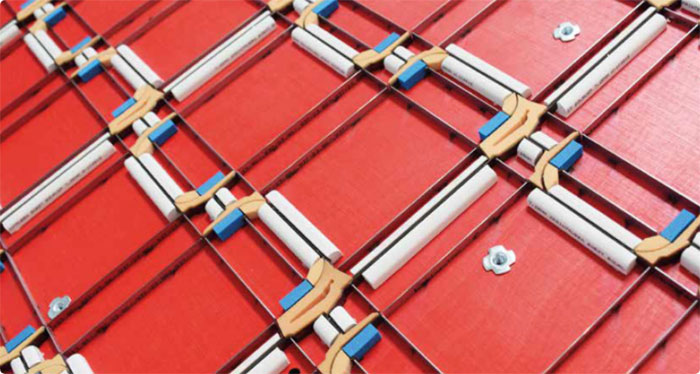

With an innovative, no-screw, quicklock design, single-person set-up, and simple integration of all sizes of cutting die, Easy Locker offers outstanding speed and accuracy during tool set-up. The arrangement of balancing knives ensures optimum cutting die pressure for trouble-free die-cutting.

Stripping station

The BOBST range of upgrades for the stripping section helps converters perform at the highest level of efficiency, with innovations such as quicklock functionality reducing change-over time, and ensuring rapid and effective form production and fixing.

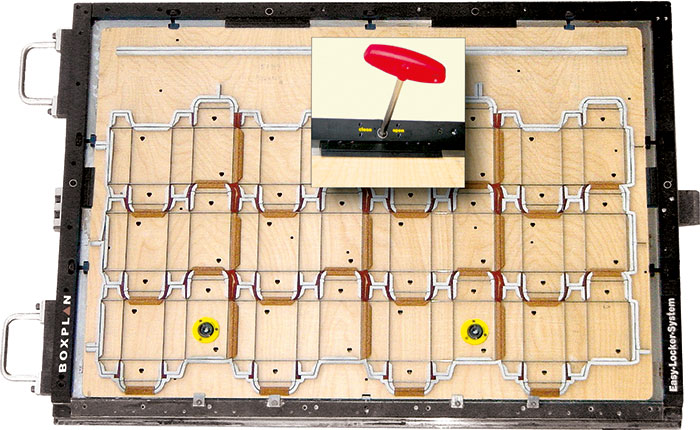

Speed Lock

The Speed Lock system comprises a complete top cassette and bottom locking device. It allows operators to finely load stripping sandwiches into cutting and creasing presses as quickly as possible, without the need to spend time aligning and screwing, or stripping frames and upper blanking tools. Suitable for all sizes of stripping board and die-cutters, Speed Lock allows converters to quickly respond to the changing requirements of brand owners.

Blanking station

BOBST blanking section upgrades allow for fast and efficient setup of effective blanking forms, so that converters can produce high-quality packaging, while reducing costs and saving time.

Blank Lock

The Blank Lock system lets users position forms quickly, without the need to align and screw male blanking forms. It also has a standardized, single-person method to ensure accurate positioning in the shortest possible time.

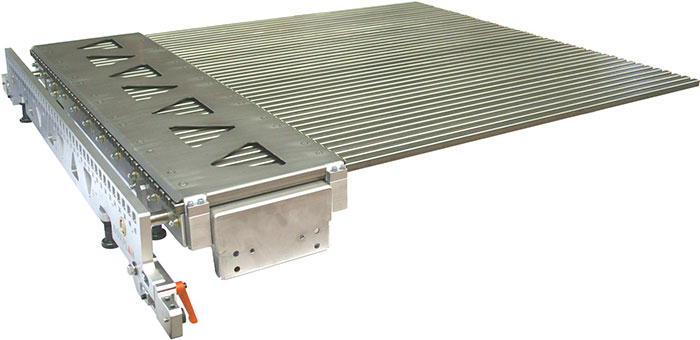

Flex Rack

Flex Rack enables the fast set up of delivery non-stop bars, without having to manually lock, position and move individual bars into die-cutter rear brackets, saving countless hours of work. Flex Rack is available for use with most BOBST die-cutters with blanking units. Watch our Flex Rack video to find out more.

Blank Fix

Designed for quick set-up, through simple handling and no screwing, Blank Fix is a universal upper blanking form made for use with all die-cutters with an integrated blanking unit. The product allows for complete standardization, short runs and fast production speeds.

Consumables

BOBST provides most consumables required for every BOBST stripping and blanking tool. With full availability and fast delivery, it means converters can operate at optimum efficiency and with total confidence, without the need for expensive stock holding.

For more information on BOBST's class-leading range of converting products, please contact our experts.

Zone Service Director - Customer Service

Hotline number : +1 973 226 8000

Office hours : 08:30 - 17:00 EDT