The importance of the cutting plate in the folding carton die-cutting process

Folding Carton converters face several challenges in their process throughout the whole production chain. One of them is related to the high impact of the cutting plates on the die-cutting process, mostly related to the quality of the cutting and creasing, final stacks consistency, and overall waste generation.

Currently, 80% of Latin American converters jobs are processed with 1.0 mm cutting plates, and many are stored and reused, aiming at gains in machine preparation time and reduction in the final cost of the operation. This way, the operator does not have to reapply the creasing counter parts.

It is important to consider that the life span of a cutting plate is determined by its hardness, directly influencing the number of strokes that it can take at the same point without sacrificing the stability or quality of the creases. If the life span of the cutting plate is not observed, deviations such as dust, “cutting burr”, sheets sticking to the tool and bursting of notches can happen more frequently during production, causing more machine stops, that ultimately result in lower productivity, loss of product quality and increased waste.

Therefore, it is important to know the correct technical specifications and the hardness of the cutting plate according to each specific production need. This will assist in the ability to determine the cutting point and life span of the tooling.

See below some types of cutting plates and their characteristics:

185 HV Plate

- For smaller runs - 200.000 up to 300.000 strokes - can be used for jobs with different layouts

340 HV Plate

- Can be used for longer runs

- It can take up to 1 million strokes used with the same tooling

- Recommended for half cut jobs

500 HV Plate (extra hard)

- Can be used for runs of over 2 million strokes

- Recommended for half cut jobs

- Can be used on both sides

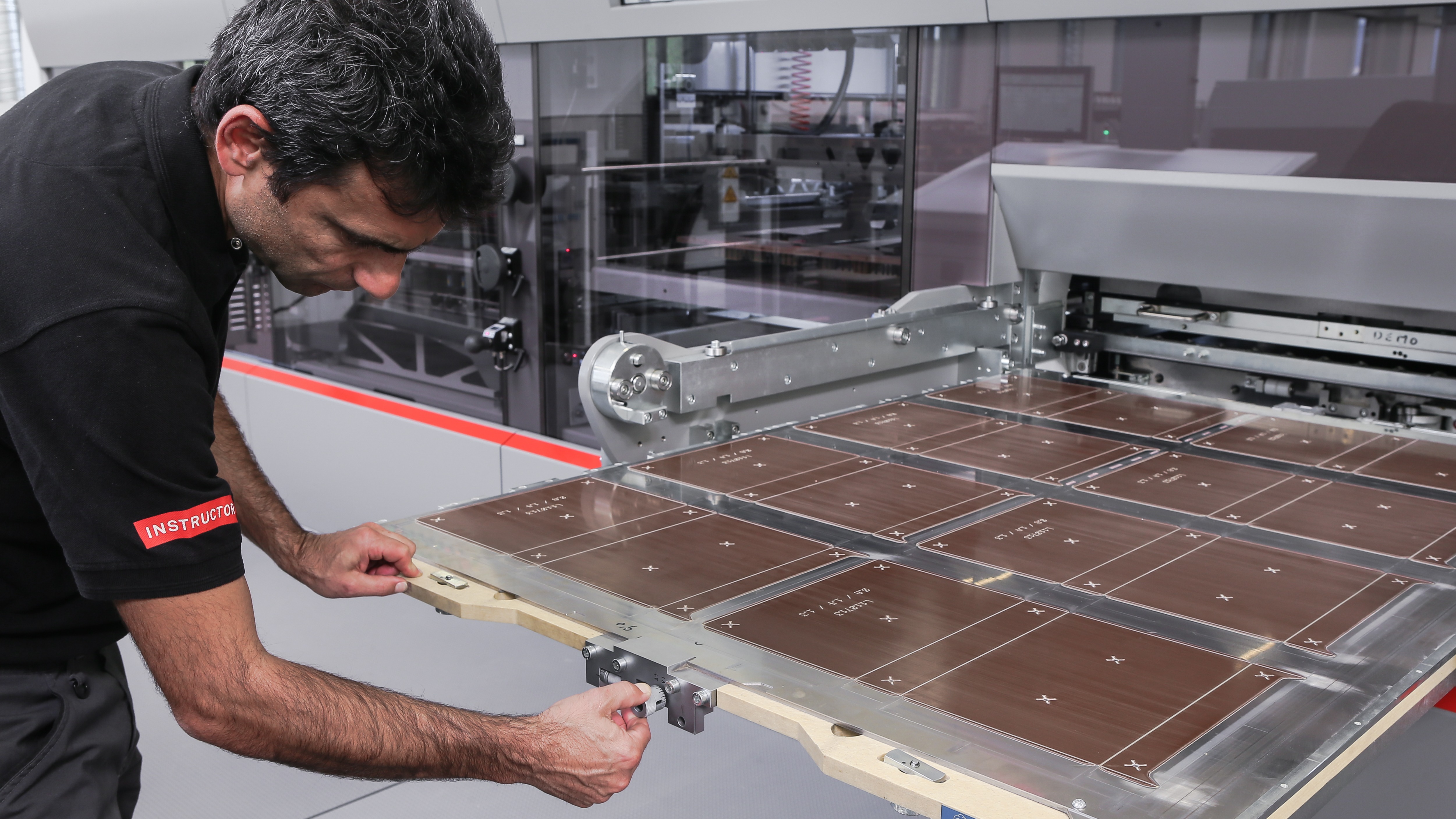

“There are some specificities of the die-cutting process that can only be ensured when correct selection, use and maintenance of the cutting plates is taken in consideration, mainly excellent leveling, faster setup, machine safety and reduction of maintenance downtime” explains Edilson Alves da Silva, Technical Instructor for Die-Cutters at BOBST.

It is crucial to understand the importance of the quality of the cutting plate to develop a productive and profitable process, since it has a great impact on the quality of the final product. High quality cutting plates to support the entire process can be purchased directly from BOBST, with the support of BOBST sales representatives.

This is one of the fundamental steps to promote excellence in each stage of the production process, to guarantee the highest quality packaging for the market.

BOBST