VISIONFOLD 50 | 80 | 110 - Folder-gluer

Feeder

- Blank aligning device available

- Set up quickly and rapidly

- Variable speed independent drive

- Adjustable on the run

- Easy repeatability

- Light maintenance

- Feeds most types of materials

- Handles most box styles

Prebreaker

- 180° prebreaking of all boxes at high speed, regardless of material

- Long prebreaker for perfectly flat glue flaps

- Extra wide lower left-hand belt ensures no marking

- High speed re-opening plough

- Upper left conveyor displacement allows for more flexibility

Crash-lock module

- Processes multiple-fold packaging

- Prebreaks large boxes and provides a location for supplementary devices such as label inserters

- Telescopic upper conveyors easily be adjustable to box format

- Allows for front panel folding

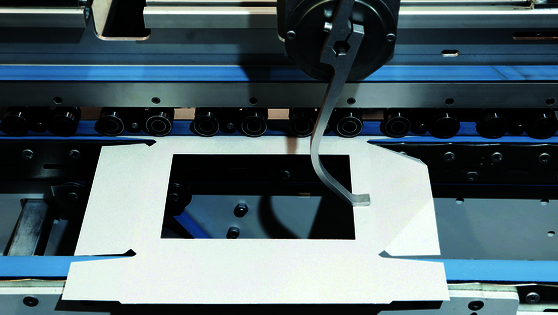

4 & 6-corner device

- Fast set-up of all types, and most sizes, of 4 and 6-cornered boxes

- Speeds of up to 22,000 b/h

- Tilting frame adjusts to flap size

- Cable guides for 45° panel

- HMI SPHERE control allows for saving of settings, automated positioning and remote control

- Modulated hook trajectory for high speed, high quality production

- Transparent security doors, reducing footprint at the back of the machine and offering space for tool storage

Lower gluing unit

- Oversized stainless steel glue wheel for high speed running

- Unique scraper device with micro-metric adjustment for precise gluing

- All components easily removable for quick cleaning

Folding

- Minimum folding device for folding down to 35 mm

- Choice of left, right or simultaneous folding

- Automatic belt tensioning ensures quicker makeready

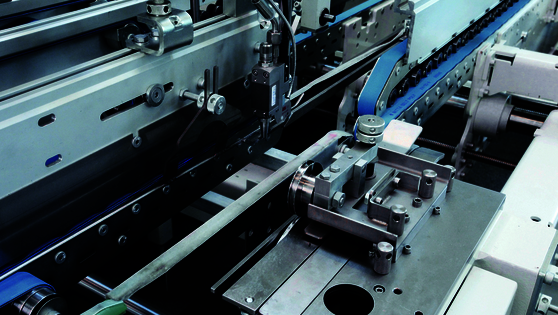

Transfer

- Independent drive for complete control and faster job change

- Synchronized kicker adjusts to carton arrival time

- Adjustable transfer conveyors adapt to difficult box shapes

- Flipper-ejector or rotary ejector device ejects non-conforming boxes

- Height adjustable for a perfect box stream

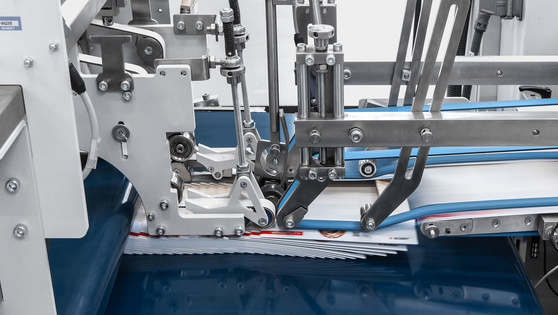

Delivery

- Integrated box stream regulator for precise stream intervals and faster running

- Automatic apron centering improves box quality and prolongs belt life

- Infeed conveyor for better control of boxes with irregular edges

SPHERE

- Controls all functions the machine

- Up to two 15” full color, high-definition touch screens

- Simple step-by-step procedure guides the operator through the job set-up process

- All settings appear on one screen for more convenient and intuitive navigation

- Fully compatible with the digital BOBST Connect platform

- Allows the saving of up to 5,000 job settings