NOVAFOIL 106 - Hot foil stamper

Feeder

- Latest generation feeder head with suction units for smooth feeding

- Stainless-steel feeding table, belts and anti-static steel plate guarantee ideal material flow

- Controllable sheet arrival for perfect synchronization and reduction of machine stoppages

HMI SPHERE

- SPHERE provides a single point of control for all functions of the machine

- Intuitive and operator-friendly navigation with step-by-step setup

- Possibility to recall of up to 5,000 job settings

- Allows swift setups and changeovers for more machine uptime

- SPHERE allows machines and data to be connected in one comprehensive platform

ACCUREGISTER

- Optional “No sheet-edge contact” system guaranteeing perfect register quality

- Large correction range in front and lateral direction

- Higher machine performance by reducing feed-related production stops

- Less waste during set up and production

Platen section

- Dedicated hot stamping transfer section

- Increased dwell time, high stamping pressure and stable temperature guarantee exceptional embellishment quality

- Reduced patching time, faster setup

- Impressive uniformity and precision

Cross film transfer and hologram application

- Inline film supply with up to three advance shafts, combined with optional cross film-transfer module with two advance shafts provide maximum versatility

- Allows application of intricate designs and one-pass productivity

- The machine can also be equipped with up to 10 dedicated modules for extremely efficient hologram application

Efficient production

- Powerful gripper bar advance system for smooth sheet transport

- Great machine stability, ensuring production continuity and product quality

OACS Connect

- The Optimal Advance Computing System (OACS) calculates optimal film advance, ensuring important savings in film use and setup time

- With OACS Connect, film advances can be calculated remotely according to different priorities and sent directly to the machine, without operator intervention

- Enables pre-production film use calculations for predictable cost and supply chain planning

Adaptability and control

- Easy and safe sampling for quality control during production

- Different equipment packs allow to further adjust the production for specific materials

- Paperfree quality control with the Digital Inspection Table (DIT) 106 ensures precision and traceability

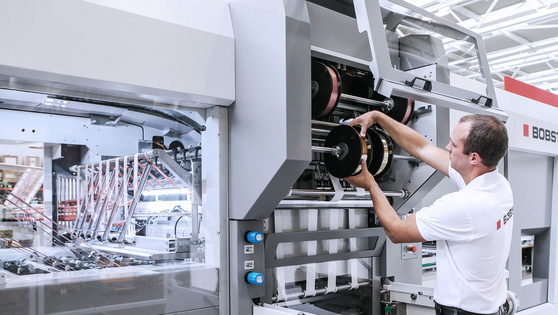

Ergonomics

- Easy access to all functions and settings, including hot stamping transfer area

- Pivoting film unwinding unit for fast and easy roll change

- Optional lift to easily load heavy rolls

- Small footprint, compact machine

- With the Digital Makeready Tool, the complex die-positioning process can be considerably simplified and shortened