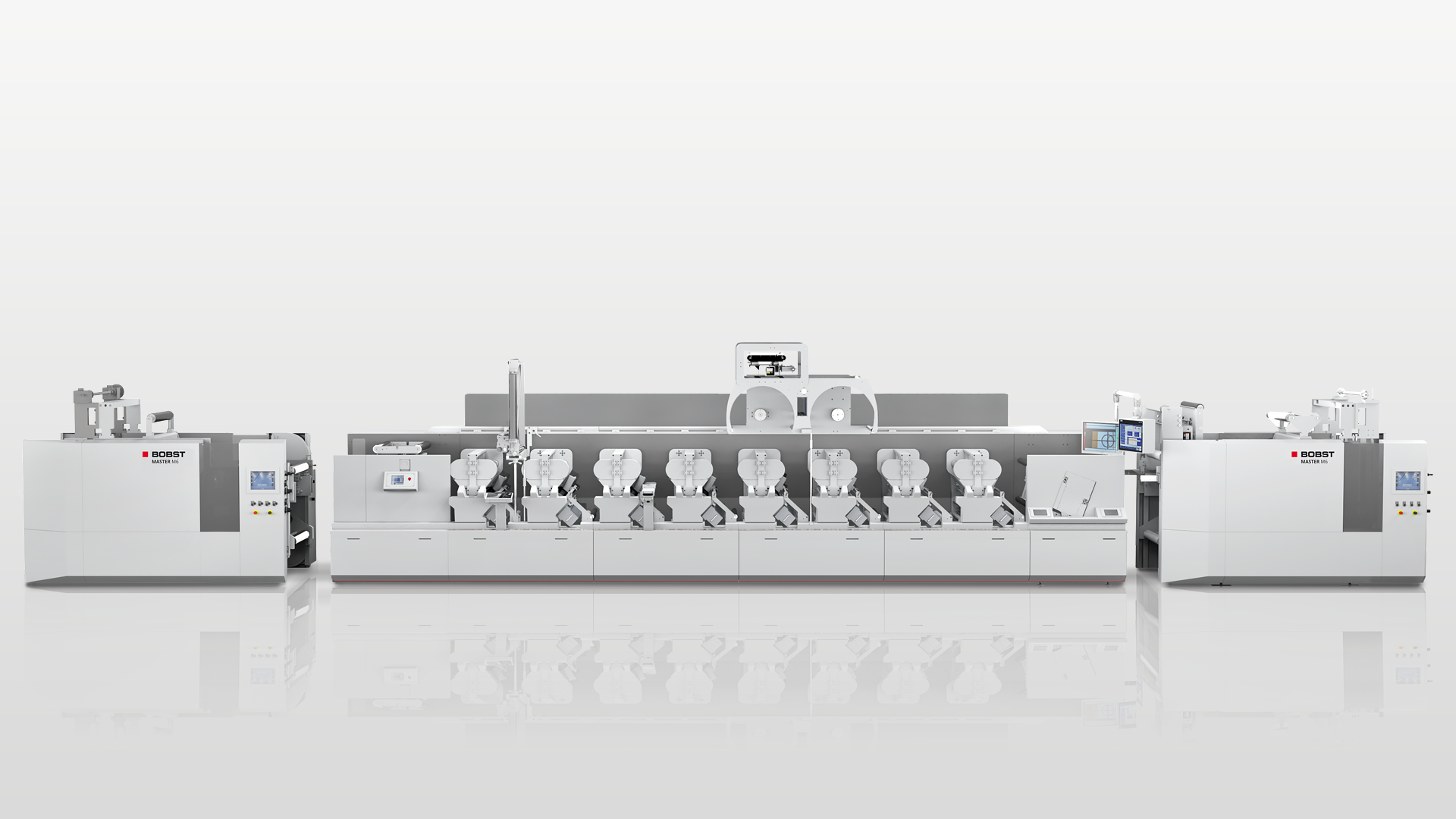

MASTER M6 - Flexo press

Exceptionally productive label & flexible packaging press

The MASTER M6 is designed for the foremost flexibility to print labels, flexible and folding carton. The monitoring systems it can be fitted with, guarantee the health and safety of food packaging applications. The press is equipped with DigiFlexo automation and oneECG technology delivering non-stop production through a centralized fully digitalized press operation.

All run lengths, all applications, all industries

- The press handles all types of substrates used to produce labels, flexible packaging or folding carton

- Multi-process, product enhancing and inline finishing applications

- Outstanding print quality and color consistency and repeatability.

Highly productive

- DigiFlexo for full digital registration and pressure controls

- Very short set-up time and waste

- Excellence solutions for automatic exchange of printing cylinders and of die-cutting stations without stopping the press

Outstanding solution for food packaging

- Exclusive total traceability system for food packaging applications with UV Track. The UV emission is monitored while the press is running with certification of the whole printing process. This opens new opportunities for UV printed food packaging production.