Processed materials

By focusing on the core strengths required to achieve the highest, fastest and most consistent level of performance since 1960, we have developed a range of technologically advanced laminating solutions and processes that meet the requirements of all segments of the market.

The continuous success of BOBST laminating machinery is quite simply because the strengths of the equipment are consistent with what is important to its users - ease of operation, high performance, little wastage and low impact on the environment.

Paper

Paper is a fibre-based material produced from wood, rags or organic material. The types of paper used in the packaging and graphic arts industries typically use wood and/or recycled paper and board, which is then chemically or mechanically processed to produce cellulose pulp. This pulp is bleached and processed in a paper making machine to produce reels of paper which may optionally be coated or finished to provide a better surface and/or improved visual appearance.

Paper may be between 0.07 mm and 0.18 mm thick, with paper for printing and packaging applications generally being in a range between 60 and 120 gsm. The crossover point between paper and board is normally considered to be around 160 grams per square meter (gsm), as it is only at this level that a fibrous material is likely to be stiff and rigid enough to make a container.

Paper has a wide range of industrial applications including use for the packaging of products as diverse as confectionery and cigarettes, as a component in packaging laminates, and for many commercial print uses.

Film

A film is usually characterized as a thin synthetic resin layer. There are many types of films and their use depends on their physical and chemical properties, which make them especially suitable for a given application.

The most commonly used plastic films are low density polyethylene (LDPE), Polypropylene (PP), bioriented polypropylene (BOPP), and polyester (PET).

Printed film is used for packaging, display materials, stickers, seals, and a wide range of other graphic applications.

Films are generally characterized by their basis weight, expressed in g/m²; and thickness, expressed in microns. For some films it is also useful to know their density, expressed in g/cm3.

The increasing awareness of environmental issues is intensifying research into film substrates derived from renewable sources that are compostable.

Aluminium foil

Aluminum is produced from bauxite, an ore abundant in nature. From the rolling mill, aluminum foils emerge with a natural shiny finish, almost as bright as a mirror, but also can be produced with an as-rolled, satin-like finish called matte.

Aluminum foil has all of the unique functional characteristics of the aluminum alloy from which it is made.

Because of its exceptional barrier properties, aluminum foil is used across a wide range of flexible and other packaging applications to protect foods, drugs, cosmetics, and a lengthy list of other items, most often in combination with other packaging materials.

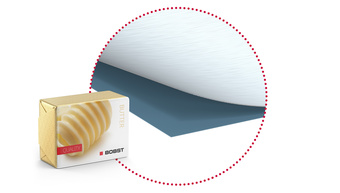

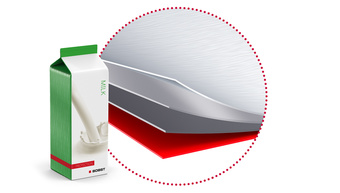

Laminates

A laminate is a material that can be constructed by bringing two or more layers of material together. This can include different material combinations from a wide spectrum of flexible substrates including thin aluminum foil, film, and paper. These materials have different physical properties and varying thicknesses that combine to provide the required barrier performance.

Converted single- or multi-layer webs are used in a number of industries, from the packaging of food and non food products to industrial applications including the photovoltaic industry.

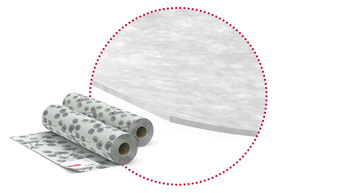

Non-woven

Non woven textiles are unique, high-tech, engineered fabrics made from fibers.

In combination with other materials, or used alone, non wovens are used to create a wide range of consumer and industrial products with diverse properties, including:- absorbent hygiene products; apparel; home furnishings; healthcare and surgical fabrics; construction, filtration, and engineering materials; and wipes.