Vacuum metallizing process

Designed for wide web processing, BOBST vacuum coating and metallizing machinery is characterized by minimal downtime and superb quality at high speeds, which is why BOBST is noted as the world's premier supplier of vacuum coating and metallizing solutions for barrier, decorative, security and high technology applications.

Vacuum coating and metallizing process

Vacuum coating and metallizing is the process of adding a thin film of aluminum or other coating to a material.

In principle, the process calls for the evaporation of the coating material inside a vacuum chamber, after which it condenses onto a web of substrate as it passes through.

Paper and film metallizing is utilized in the packaging and decorative market segments. The barrier and decorative markets are noted for their wide variety of products from beer labels to chip bags.

Vacuum coating machines

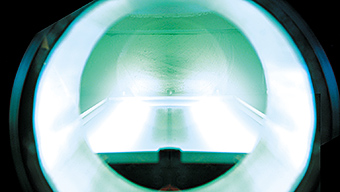

A vacuum coater, also referred to as a vacuum metallizer or barrier coating machine, consists of a vacuum chamber which has been evacuated to, typically, 0.0005 mbar.

Inside this chamber, aluminum wire is fed onto individual, resistance-heated inter-metallic evaporators, where the aluminum becomes molten and evaporates.

The flexible substrate, supported on a chilled process drum, passes over the evaporation source at speeds of up to 1000 m/min. The aluminum vapor condenses onto the substrate and so creates the coating layer.

Plasma treatment

A plasma treatment unit can also be used as part of a vacuum coater system in order to enhance metal adhesion and/or to improve the substrate's qualities as a barrier against oxygen and water vapor transmission. Here, the surface of the web is hit by plasma just prior to the coating process.

The plasma is formed by applying an electrical voltage to a gas, or combination of gases. In addition to removing moisture and other contaminants, plasma treatment acts to increase the number of nucleation sites by the introduction of polar groups, resulting in a coating with a homogeneous surface morphology and fewer defects.

Applications

The vacuum coater is used to deliver aesthetic improvements to flexible substrates and/or to reduce oxygen and water vapor transmission to levels similar to that of glass and metal containers. This delivers improved packaging performance, extends pack shelf life and maintains the quality of the packaged product.

The process can also be used to produce substrates which conduct electricity, save energy, control light transmission or reflection, and which can even help prevent counterfeiting or theft.

BOBST expertise and knowledge

Through its General product line, BOBST has formidable expertise in the vacuum coating process and in handling flexible substrates. This has led to the development of high technology vacuum coating and metallizing lines that can be used to produce a wide variety of products.