Transparent MDO PE solutions as an alternative to Metallized Polyester

BOBST & its partners, Dow and Hosokawa Alpine have developed innovative High Barrier, Recyclable MDO PE Mono-material solutions in response to the industry’s greatest challenge of sustainability. One such solution incorporates the BOBST AlOx Integrated Conversion Solution to produce a transparent full PE mono-material duplex laminate with the barrier performance of metallized polyester film.

BOBST Integrated AlOx Solution

The BOBST Integrated AlOx Solution is about more than just the machine platforms, it encompasses the experience and process knowledge of experts across the value chain for optimised polymer raw materials (DOW), film production (Hosokawa), vacuum coating, wet offline top coating, printing and lamination of AlOx coated barrier films. In addition, BOBST consumable knowledge means that recommendations can be given on topcoats, inks and adhesives. All of this combined, gives a strong customer focus which helps in the building of relationships.

Trial Platforms and Processes

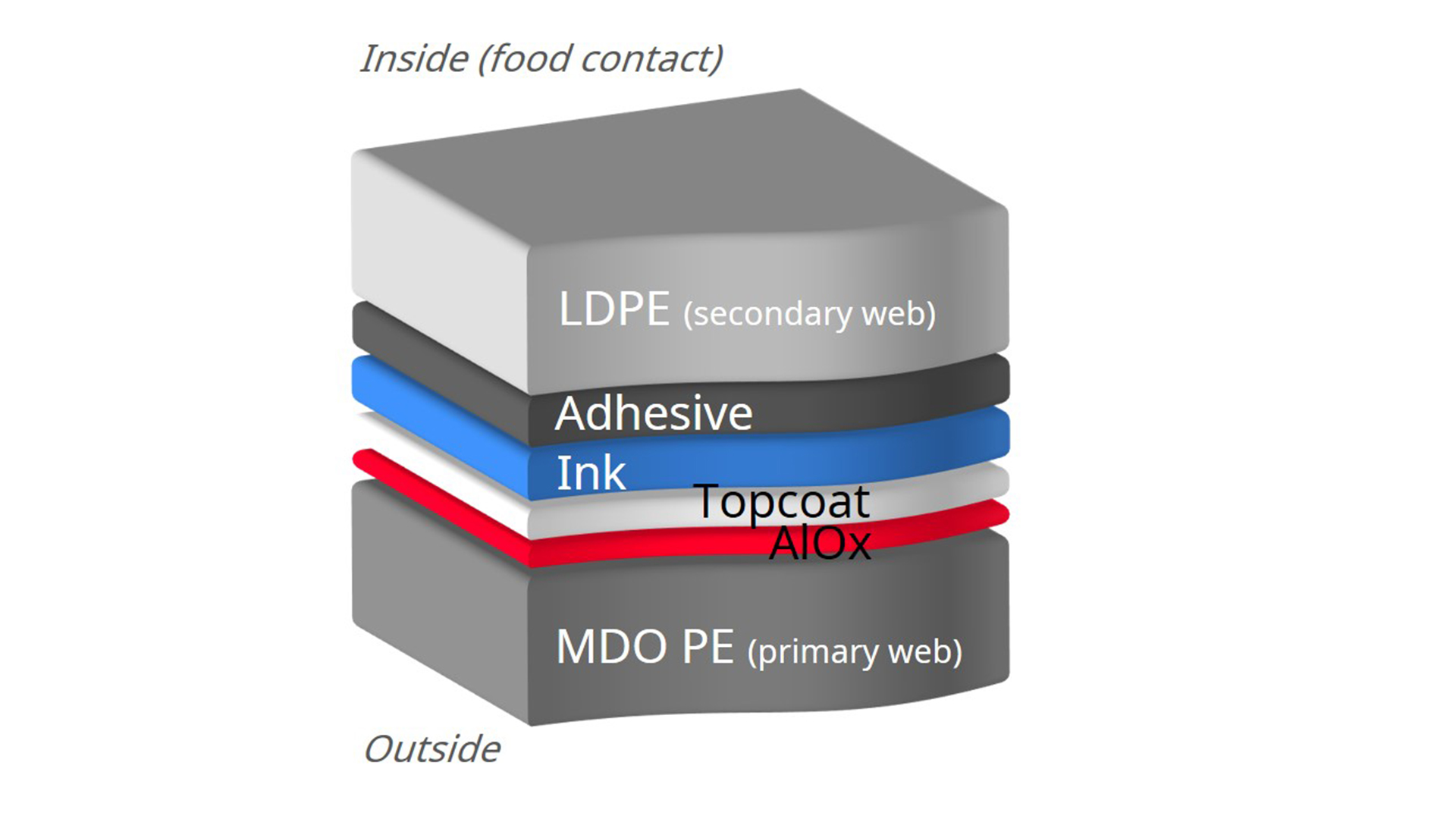

The work resulted in the production of a duplex laminate (see figure 1).

The entire conversion chain has been investigated, this means the film production, vacuum coating, top coating, printing, lamination and pouch making steps have all be carried out. The vacuum coating was done at Bobst Manchester’s Centre of Excellence for High Barrier on an EXPERT K5 2900mm; top coating was also done in Manchester on a NOVA CO 750.

Once the material has been topcoated, there is no need to worry about conversion and standard equipment under standard conditions can be used without affecting the barrier performance. For the printing stage, reverse printing was carried out at Bobst Bielefield on an EXPERT CI and lamination was then done at Bobst Italia on a VISION CL 850.

Conversion Trial Summary

Two different film types were explored, the first was a standard MDO PE with a polyethylene based skin and the second, a special engineered MDO PE with a special co-extruded skin making it very receptive to the AlOx layer (Films were 25 µm, 5 layer supplied by Dow/Hosokawa Alpine).

The BOBST Integrated Conversion Solution was applied; firstly a 8 nm AlOx barrier layer was deposited, followed by a 0.5 µm barrier lacquer which was developed with Michelman. As well as providing barrier enhancement, the topcoat also protects the AlOx through conversion to preserve the barrier performance. The film was then flexo printed with water based inks, laminated using an adhesive supplied by Sun Chemical and finally ELBA produced pouches. The target was to produce a film laminate that has metallized polyester film barrier performance but with full transparency in a full PE mono-material duplex laminate.

Results: Standard MDO PE (non-engineered surface)

On the standard MDO PE, the OTR that can be achieved with the Integrated Solution is around 0.6 cm³/(m² d) which is a very good barrier improvement from an average of 4500 cm³/(m² d) for the base film. This figure is further enhanced by the printing and lamination steps down to around 0.1-0.2 cm³/(m² d) due to the barrier adhesive. Moisture barrier is around 3.5 g/(m² d), again this is further enhanced by the printing and lamination down to 2.5 g/(m² d). During pouch making, some of the oxygen barrier is lost but this is to be expected as pouch making is quite a demanding process, but the OTR is still well below the target of 1cm³/(m² d) which is the metallized polyester film equivalent.

In addition to the barrier testing, the laminate has also been put through flex durability testing using a Gelbo Flex tester. This is quite an aggressive test where the sample is flexed and crushed repeatedly. This is to simulate what might happen to packaging material when handled in the transport, storage or retail environments and shows the worst case scenario. You can see from the graph that some oxygen barrier was lost but it is still below the target of 1cm³/(m² d).

Results: Special skin MDO PE (engineered surface)

With the Integrated Solution on the engineered MDO PE, OTR is obtained of around 0.4 cm³/(m² d), again this is further enhanced by printing and laminating to 0.13 cm³/(m² d). Moisture barrier is around 4 g/(m² d), again enhanced to around 1.7 g/(m² d) by the printing and lamination steps.

Also for the engineered film, the flex durability testing has been carried out. Looking at Figure 5, it can be seen that there is not much impact on barrier; this demonstrates that when the AlOx layer is encapsulated between the special skin and the barrier topcoat, the layer is protected and the barrier performance is maintained even in very aggressive and damaging conditions.

For more information on this solution, please contact your usual sales representative or email here

Bobst Manchester Ltd, United Kingdom