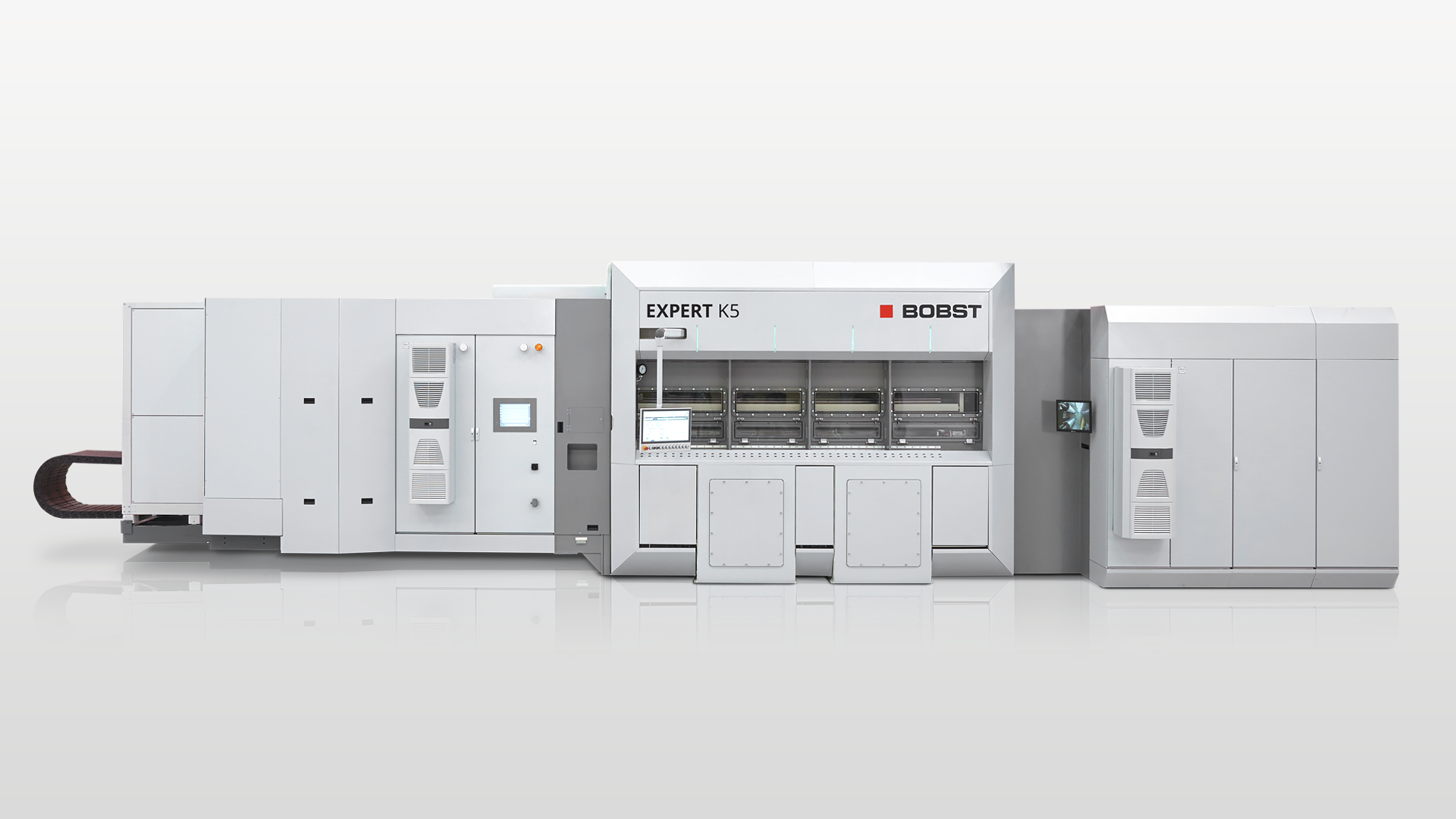

EXPERT K5 Metallizer

High productivity metallizing

Outstanding performance

- High speed metallizing

- Ability to house increased roll diameters up to 1,270 mm

- Largest coating window in the industry with improved collection efficiency of 16%

- Largest diameter coating drum in the industry at 700 mm

- Easy to operate with an Automatic Sequential Control (ASC) system

- Incorporates the BOBST renowned winding mechanism.

Energy saving and waste reduction

- ECO mode reduces energy consumption by up to 50% during standby

- Film Save mode minimises amount of film waste to less than 400 m per roll

- 15% more aluminium deposited on the web

- Reduced carbon footprint.

Lowest production costs in the market

- Reduced production cycle increasing number of rolls per day

- 20% savings in production costs

- Maximum machine uptime

- Total Cost of Ownership reduced by up to 25% compared to competitors.